Boost Production with Our Heavy-Duty 100-300 C-Shaped Roll Formers

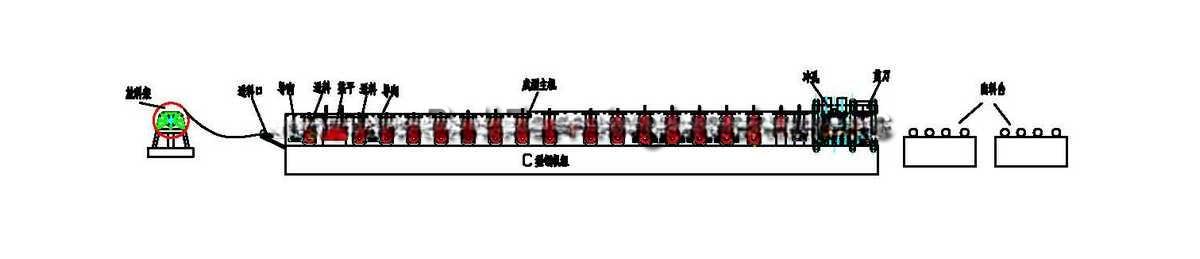

100-300 C-Shaped Roll Formers are the backbone of efficient metal profile production. As a leading cold roll forming machine factory, we build these robust machines to deliver reliability, speed, and precision for your manufacturing needs.

What Are C-Shaped Roll Formers?

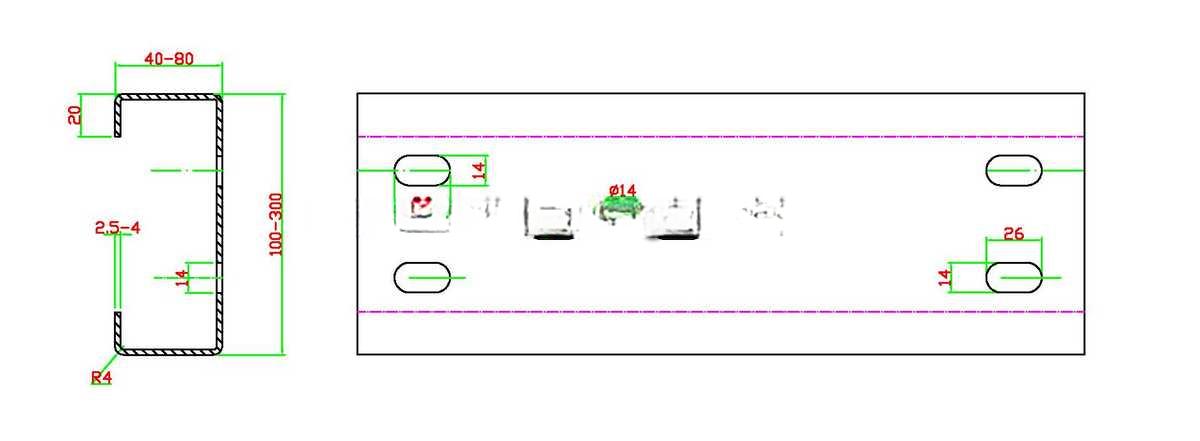

First, let’s define the machine. A cold roll forming machine shapes long strips of metal coil into specific cross-section profiles. Our focus is on the popular C-shape, also known as a C-channel or C-purlin. These profiles are vital in construction, shelving, and framing. Our machines handle a versatile range from 100mm to 300mm in profile size. This makes them perfect for many different projects.

Key Features of Our 100-300 C-Shaped Roll Formers

Our machines stand out due to their superior construction and performance specs. Here are the critical features:

-

Product Range: The machine forms C-shaped steel profiles from 100mm to 300mm. This covers most common industrial and construction requirements.

-

High Working Speed: It operates at an impressive 12 to 15 meters per minute. This speed is for the forming process itself, before adding cutting or stacking units. Consequently, it ensures high-volume output.

-

Robust Roller Design: We use 25 roll stations, with 7 dedicated to initial flattening. The rolls are made from Cr12 tool steel, hardened to HRC 58-62. This guarantees long life and resistance to wear, even with hard materials.

-

Powerful Drive System: The main power is 18.5 kW, providing ample torque for forming thick materials. The hydraulic system runs at 25 MPa for reliable ancillary functions.

-

Material Capacity: It processes steel with a thickness of 2.5mm to 4.0mm. This makes it suitable for light to medium structural applications.

The machine’s overall size is approximately 11.3 meters long, allowing for a gradual and precise forming process.

Applications for C-Shaped Roll Former Products

Profiles made by our C-shaped roll formers are everywhere. They are fundamental components in:

-

Building & Construction: Used as purlins and girts in metal buildings, wall studs, and roof framing.

-

Storage Solutions: Form the uprights and beams for heavy-duty warehouse racking and shelving systems.

-

Industrial Framing: Create frames for machinery guards, workstations, and support structures.

-

Furniture & Displays: Used in the base frames for commercial furniture and retail display units.

Essentially, wherever strong, lightweight, and easy-to-assemble steel framing is needed, a C-channel from our machine is an ideal choice.

Advantages of Choosing Our Roll Forming Machines

Why partner with our factory? The benefits are clear:

-

Precision & Consistency: The multi-stage roll forming process creates identical, high-tolerance parts from coil to coil.

-

High Efficiency: The continuous operation is much faster than single-stamp presses or manual methods. Therefore, it lowers your cost per part.

-

Material Strength: The cold forming process can increase the yield strength of the steel, resulting in a stronger final product.

-

Reduced Waste: Roll forming is a near-net-shape process. It generates significantly less scrap compared to other methods.

How to Customize Your 100-300 C-Shaped Roll Forming Machine

We understand that standard specs don’t always fit. That’s why we offer full customization. We don’t just sell machines; we provide solutions tailored to your product.

Our process is straightforward:

-

Send Your Requirements: Provide us with detailed drawings of your desired C-shaped profile.

-

Specify Your Material: Tell us the type and grade of steel coil you will use.

-

Our Engineering Team Designs: We will then design a cold roll forming machine specifically for your profile. Our design ensures optimal roll sequence, spacing, and power for your exact material.

We can adjust the number of stands, the roll diameter, the cutting system, and more. Whether you need a simple line or a fully automated system with punching and notching, we can build it.

Industry Standards and Further Learning

Our machines are built to perform reliably in industrial environments. For engineers and buyers wanting to deepen their knowledge of the process, resources like The Fabricators & Manufacturers Association offer excellent insights into metal forming technologies.

Conclusion: Your Partner in Metal Forming

In summary, our 100-300 C-Shaped Roll Formers represent a smart investment for any business producing metal channels. They combine durable construction, proven design, and flexible customization.

Ready to enhance your production line? Contact our factory today to discuss your project. Send us your drawings and material specs for a custom C-shaped roll forming machine quote. Let’s build the machine that builds your success.