A 1250 slitting machine is a powerhouse in modern metal fabrication. This vital piece of coil processing equipment efficiently transforms wide master coils into precise, narrower strips. These strips are ready for the next stage in a roll forming machine line or other applications. Understanding this machine’s capabilities is key for manufacturers seeking efficiency and quality.

What is a 1250 Slitting Machine?

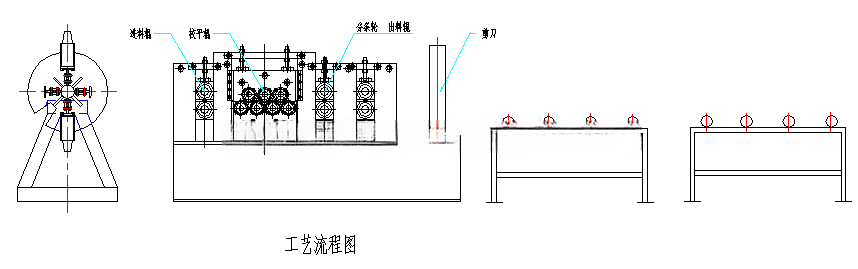

Simply put, a 1250 slitting machine handles coils up to 1250mm (or 1.25 meters) in width. It uses sharp, rotary cutter heads to slit the metal longitudinally. Consequently, it creates multiple strips in one fast pass. This process is often the first critical step before the roll forming stage, where strips are shaped into final profiles.

Key Specifications and Components Explained

Let’s break down the typical specs for a robust 1250 slitting machine:

-

Processing Capacity: It handles materials from 0.17mm to 2mm in thickness. This range covers thin gauges for appliances up to heavier materials for structural parts.

-

Line Speed: Operational speeds between 5 to 10 meters per minute ensure controlled, precise cutting. Modern machines can run even faster for high-volume output.

-

Critical Component Materials:

-

Slitting Cutters (Cr15): These are made from Cr15 bearing steel. This material offers excellent hardness and wear resistance. As a result, it ensures long-lasting, sharp cutting edges and consistent strip quality.

-

Main Shaft (45# Steel): The main draft or arbor is constructed from 45# carbon steel. This provides the necessary strength and rigidity to support the cutter heads under high tension.

-

-

Drive System: A main power motor of 11kW delivers the torque needed to pull the heavy coil through the slitting line reliably.

-

Cutting Mechanism: A hydraulic cutting unit (5.5kW) powers the side trimmers and the scrap chopper. This system cleanly removes edge imperfections and cuts scrap into manageable pieces.

-

Control System: A PLC (Programmable Logic Controller) is the machine’s brain. It allows for automated, repeatable operation, easy setup changes, and integration with other line equipment.

Why Choose a 1250mm Slitting Line? Core Benefits

Investing in a capable 1250 slitting machine brings major advantages to your workshop.

-

Superior Efficiency and Speed: It processes wide coils into multiple strips simultaneously. Therefore, it dramatically outpaces manual or single-cut methods.

-

Exceptional Precision and Quality: High-quality cutter heads and a rigid frame guarantee clean, burr-free edges. This precision is crucial for smooth feeding into downstream roll forming equipment.

-

Remarkable Material Yield: Accurate slitting minimizes edge waste. This optimization leads to significant material cost savings over time.

-

Enhanced Versatility: With quick-change cutter setups, you can switch between different strip widths and material types efficiently.

Applications in Metal Fabrication

This slitting equipment is fundamental in creating feedstock for numerous products. For example, the strips it produces are used to make roofing panels, wall cladding, shelving brackets, and door frames. Essentially, any industry using long, formed metal profiles likely starts with a slitting line.

Integration with Roll Forming Technology

A 1250 slitting machine is often the first module in a complete roll forming production line. The slit coils feed directly into the roll forming machine. There, they are progressively shaped through a series of rolls. This integrated setup creates a seamless, automated workflow from raw coil to finished profile. For authoritative technical details on slitting processes, refer to resources from the Fabricators & Manufacturers Association, Intl. (FMA).

Choosing the Right Machine: A Quick Checklist

Before you buy a 1250 slitting machine, consider these points:

-

Material Type: Confirm it handles the specific metals you use (steel, aluminum, etc.).

-

Production Volume: Match the machine’s speed and durability to your output needs.

-

Automation Level: PLC controls are essential for consistent, modern production.

-

Supplier Reputation: Choose a manufacturer known for robust construction and reliable support.

Conclusion

Ultimately, a well-specified 1250 slitting machine is a strategic asset. It boosts productivity, improves product quality, and reduces operational waste. By understanding its specifications and benefits, you can make an informed decision. This investment will strengthen your metal fabrication capabilities for years to come.

Contact us for more about cold roll forming machines.