7 Essential Benefits of a 5m and 7m CNC Bending Machine for Industrial Fabrication

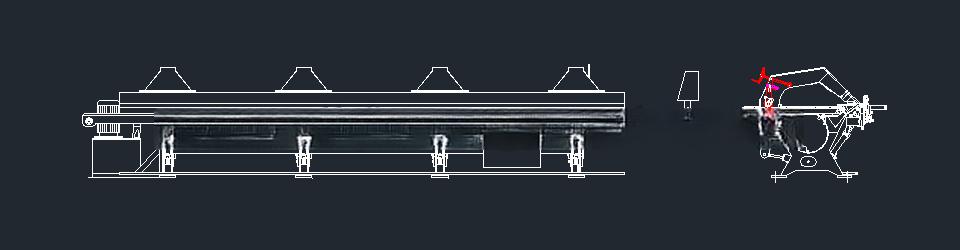

A 5m and 7m CNC bending machine represents the pinnacle of precision and efficiency in modern metal fabrication. Designed to handle large-scale industrial projects, this powerful machinery can bend steel panels up to 1.5mm thick, aluminum up to 2.0mm, and stainless steel up to 1.0mm across impressive lengths of 5000mm to 7000mm. With applications spanning roofing, doors, windows, and structural components, understanding this equipment’s capabilities can transform your production workflow.

1. Unmatched Technical Specifications and Capabilities

The core advantage of a 5m and 7m CNC bending machine lies in its robust technical design. With a maximum bending angle of 125 degrees and powered by a reliable 7.5KW hydraulic system (with an 8KW total power draw), this machine delivers consistent force for high-volume production. The substantial weight—4300KG for the 7m model and 3000KG for the 5m variant—ensures stability during operation, minimizing vibration and enhancing bend accuracy. Its generous bed size accommodates large panels, making it indispensable for fabricating architectural elements, industrial enclosures, and transportation components.

2. Material Versatility: Steel, Aluminum, and Stainless Steel

Whether you’re working with 1.5mm mild steel for structural frames, 2.0mm aluminum for lightweight architectural features, or 1.0mm stainless steel for corrosive environments, a CNC press brake of this scale handles diverse materials effortlessly. The precise CNC control allows operators to program specific pressure and stroke parameters for each material type, preventing cracking in aluminum or springback in high-strength steel. According to the Fabricators & Manufacturers Association, modern CNC brakes are crucial for adapting to varied material demands in custom fabrication.

3. Precision Engineering for Complex Applications

From creating consistent ridge caps for roofing to forming precise frames for industrial doors and windows, the long sheet metal bending machine excels in repetitive, complex tasks. The CNC system stores countless programs, allowing quick changeovers between jobs. This precision reduces material waste and rework, directly impacting your bottom line. For industries requiring tight tolerances—like aerospace or specialized machinery—this accuracy is non-negotiable.

4. Comparing the 5m vs 7m Models: Which is Right for You?

Choosing between a 5m CNC bending machine and a 7m CNC bending machine depends on your project scope. The 5m model (approx. 5938mm bed length) is ideal for standard architectural elements and smaller shop spaces, while the 7m version (approx. 7938mm bed length) tackles large panels for commercial construction and shipbuilding. Consider your most frequent bending length, available floor space, and future project pipeline when selecting. Both models share the same powerful 7.5KW hydraulic system, ensuring no compromise on bending force.

5. Integration into Smart Manufacturing Workflows

Contemporary industrial CNC machinery is no longer an isolated tool. With optional interfaces for CAD/CAM software and IoT connectivity, a 5m and 7m CNC bending machine can become the centerpiece of a digital factory. Real-time monitoring of tonnage, angle, and cycle times enables predictive maintenance, reducing downtime. Resources like Machine Design highlight how connected CNC equipment boosts overall equipment effectiveness (OEE) in smart workshops.

6. Safety, Training, and Operational Best Practices

Operating heavy-duty fabrication equipment requires strict adherence to safety protocols. Modern hydraulic bending machines feature light curtains, two-hand controls, and emergency stop systems. Investing in comprehensive operator training—covering CNC programming, tooling setup, and machine maintenance—maximizes both safety and productivity. Properly trained teams can leverage the full potential of these machines, from simple bends to intricate multi-stage forming.

7. Future-Proofing Your Fabrication Shop

Investing in a large-format CNC bending machine is a strategic decision for business growth. As demand for larger fabricated components increases in renewable energy, infrastructure, and transportation, having a 7m capacity positions you to win bigger contracts. The durability and adaptability of these machines, with regular maintenance, ensure a strong return on investment for years.

In summary, a 5m and 7m CNC bending machine is more than just a tool—it’s a productivity multiplier for serious metal fabricators. By offering unparalleled precision across vast working lengths and diverse materials, it addresses the core challenges of modern manufacturing. Evaluate your needs, explore the specifications, and consider how this powerful equipment can elevate your fabrication capabilities to meet tomorrow’s demands.

Contact us now.