The Essential Guide to the Powerful 6-Inch Water Channel Machine: Unlock 95% Production Efficiency

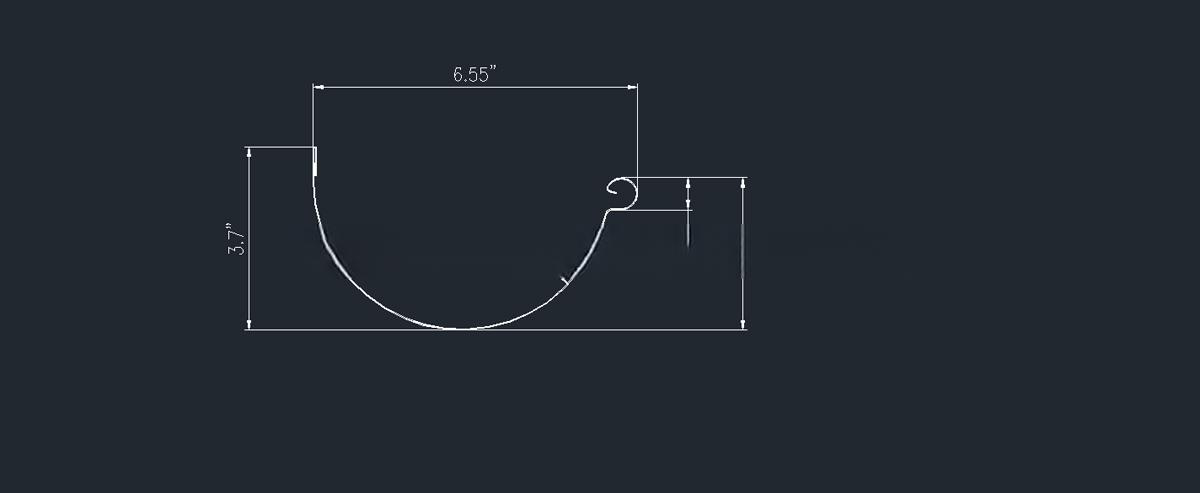

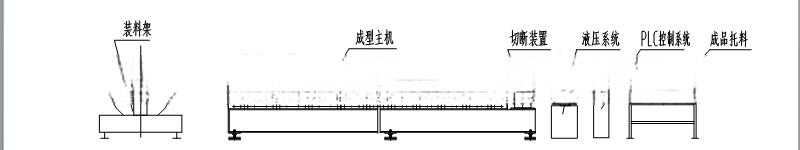

The 6-Inch Water Channel Machine is a specialized piece of industrial equipment engineered for the efficient, high-volume production of steel drainage and irrigation channels. Also known as a channel roll forming machine, this system transforms coiled steel into precise, uniform U-shaped channels through a cold roll forming process, making it indispensable for construction, agriculture, and municipal infrastructure projects.

Why a 6-Inch Water Channel Machine is Essential for Modern Drainage

In an era demanding robust infrastructure, the ability to produce standardized drainage components on-site or at a factory offers immense logistical and cost advantages. A dedicated channel forming machine ensures consistency, strength, and speed that manual fabrication or alternative methods cannot match. This machine is specifically calibrated to handle the common 6-inch (approx. 150mm) channel profile, a standard size for roadside drainage, field irrigation, and site management. Investing in this technology translates to reliable output, reduced material waste, and a faster project turnaround.

Key Specifications of a Modern 6-Inch Water Channel Machine

Understanding the core specifications is vital for operation and procurement. Here’s a breakdown of a standard model’s capabilities:

-

Forming Specification: Can process material up to 300mm in width, with a thickness range of 0.4mm to 0.6mm. The length (

*L) is typically customizable via a flying cutoff system. -

Material Grade: Designed for steel with a minimum Yield Strength of G195MPA, ensuring the formed channels have the structural integrity for load-bearing applications.

-

Production Speed: Operates at a working speed of 10 to 12 meters per minute, balancing high output with forming precision.

-

Forming Stations: Equipped with 18 primary forming stations, plus additional assist rollers. This high number of stations allows for a gradual, precise shape transition that prevents material stress and ensures a perfect final profile.

-

Core Component Materials:

-

Rollers: Made from 45# carbon steel with a chrome-finished surface for exceptional hardness, wear resistance, and a smooth finish on the final product.

-

Shafts: Constructed from 45# steel with a 65mm diameter, providing the necessary rigidity and torque resistance for continuous operation.

-

-

Power & Drive System:

-

Main Drive: Powered by a 2.2KW decelerator motor with a chain drive system, offering reliable and powerful transmission.

-

Hydraulic System: Features a 2.2KW hydraulic power unit operating at 10-12 MPA, typically used for the critical flying cutoff mechanism that shears the continuous formed channel to precise lengths.

-

Setting Up Your 6-Inch Water Channel Machine for Optimal Performance

Proper setup is non-negotiable for safety, quality, and machine longevity. Follow these key steps:

-

Foundation & Leveling: Secure the machine on a solid, level concrete foundation to prevent vibration and misalignment during high-speed operation.

-

Material Feed Alignment: Carefully align the uncoiler and feed guide with the first forming station. Improper alignment is a primary cause of material scratching and profile defects.

-

Roller Gap Calibration: Meticulously adjust the gap between the top and bottom rollers at each of the 18 forming stations according to the specific material thickness (0.4-0.6mm). Start with the first station and proceed sequentially.

-

Hydraulic & Drive Check: Verify hydraulic fluid levels, check for leaks, and ensure the chain drive is properly tensioned and lubricated before initiating a production run.

-

Test Run & Fine-Tuning: Always conduct a test run with a short coil. Inspect the final channel for dimensional accuracy, symmetry, and surface finish. Fine-tune roller pressure and alignment as needed.

Applications and Material Considerations

The primary product of this cold roll forming machine is a galvanized steel or pre-painted steel channel used in:

-

Roadside and Highway Drainage Systems

-

Agricultural Field Drainage and Irrigation Canals

-

Parking Lot and Site Surface Water Management

-

Foundation and French Drain Applications

The specification of processing G195MPA yield strength steel means it can handle commercial-quality galvanized coils. For highly corrosive environments, consider using coils with higher zinc coatings or aluminum-zinc alloys. The machine’s design, as highlighted by resources like the American Society of Civil Engineers (ASCE), aligns with the need for durable, standardized civil engineering materials.