The Ultimate Guide to Our Heavy-Duty 80-300 C Purlin Roll Forming Machine

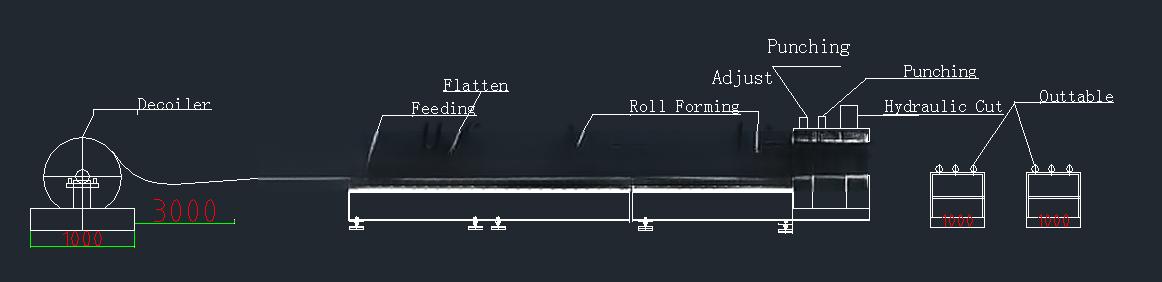

If you need to produce strong, consistent steel frames for buildings, our 80-300 C purlin roll forming machine is your ultimate industrial solution. This powerful machine transforms flat steel coils into precise C-section purlins, which are vital for roofs and walls in warehouses, factories, and large sheds. For a deeper understanding of cold-formed steel sections and their structural standards, refer to resources from the American Iron and Steel Institute (AISI).

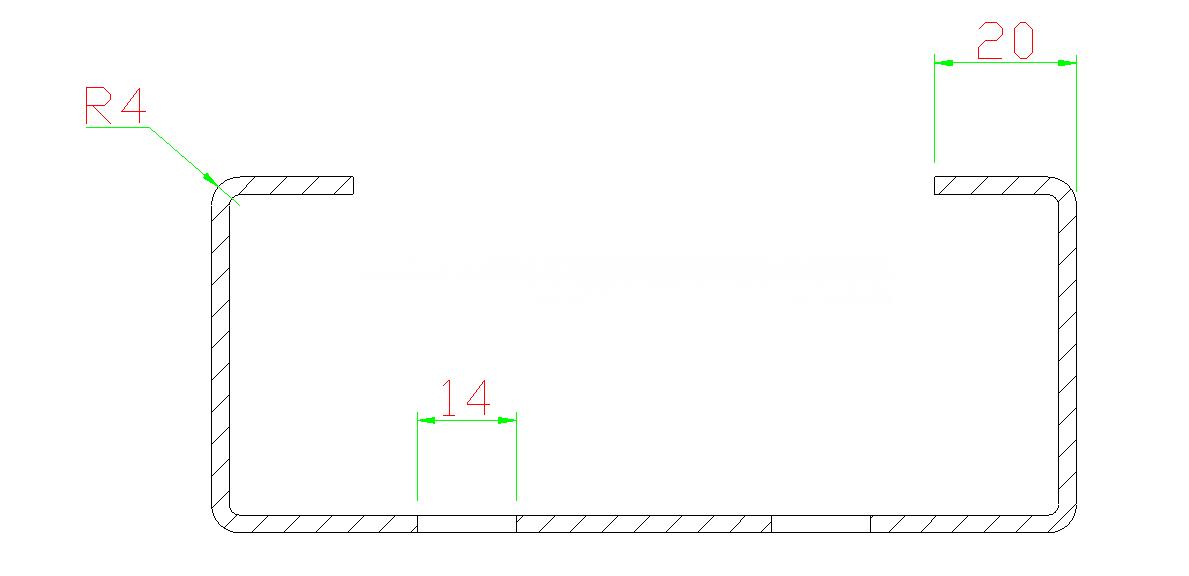

Firstly, let’s examine its core capability. This C purlin production machine expertly forms purlins from 80mm to 300mm in depth. Therefore, it offers incredible flexibility for various construction needs. A smaller 80mm purlin might support a light roof, while a robust 300mm section forms the backbone of an industrial structure. Consequently, one machine can meet diverse project demands, maximizing your investment.

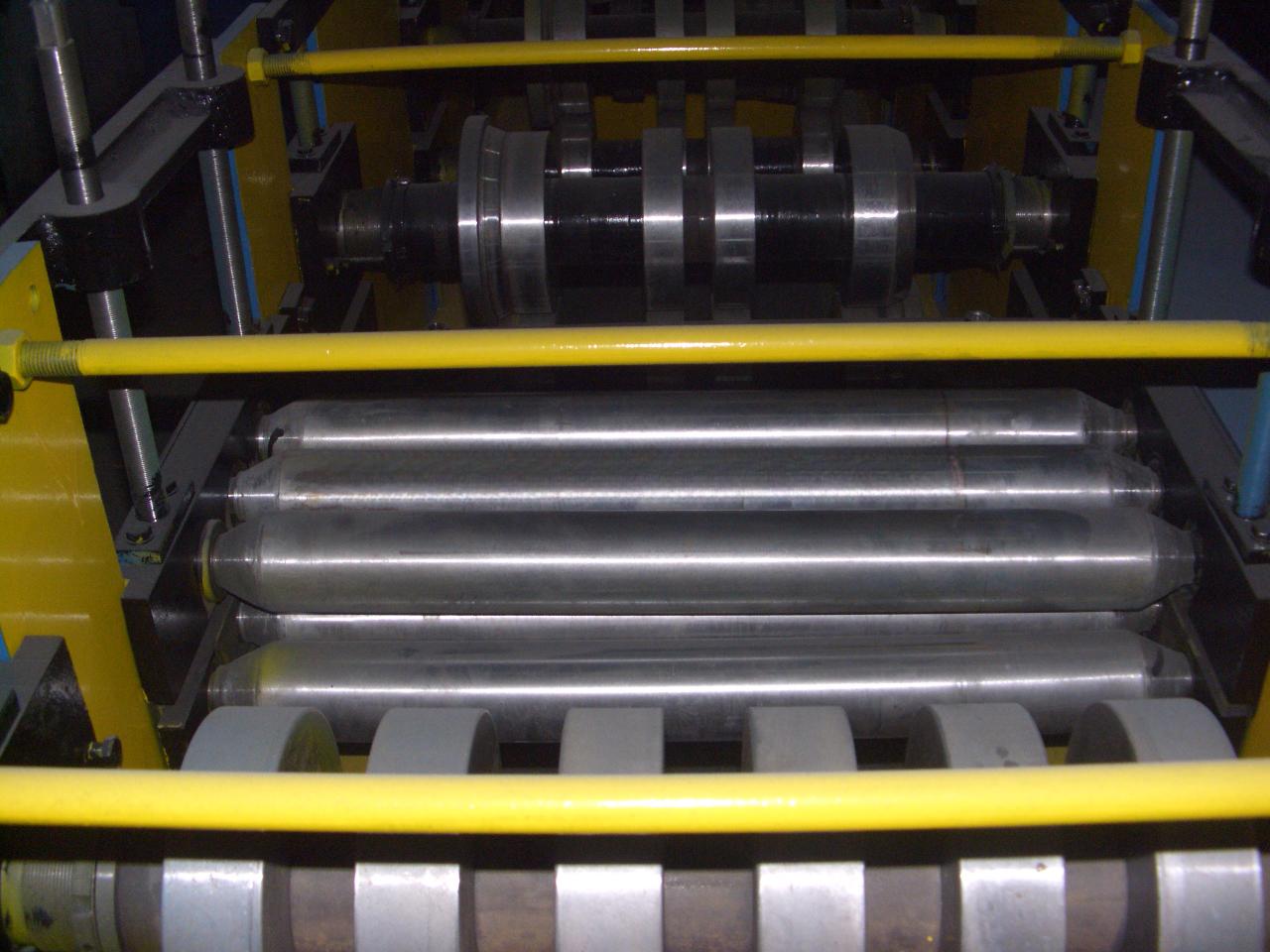

Unmatched Precision with 25 Roll Forming Stations

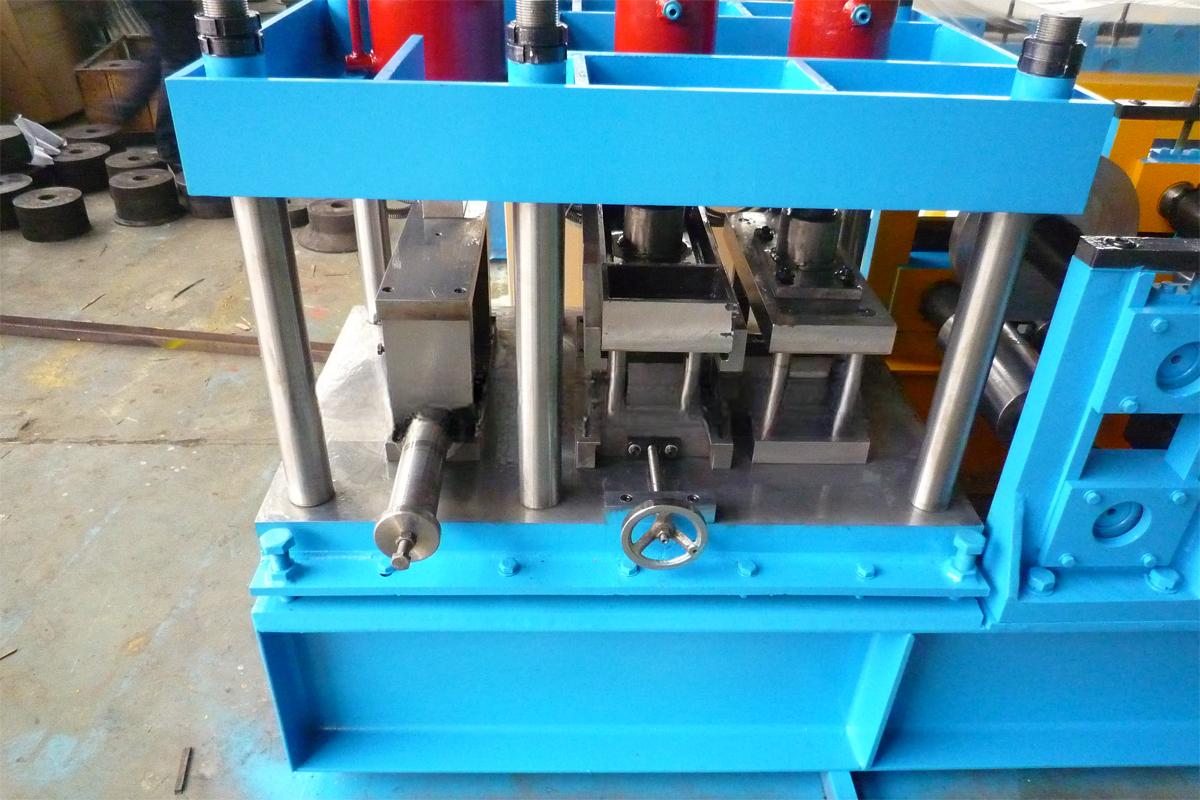

The heart of this machine is its 25 forming stations. Each station gradually shapes the steel with absolute control. As a result, the final C purlin has perfect geometry and high strength. This precision is crucial because consistent purlins make construction faster, safer, and more cost-effective. Furthermore, fewer errors mean less material waste, saving you money.

Built for Power and Endurance: Core Specifications

This isn’t a light-duty unit; it’s built for demanding, continuous operation. Below are the key specs that define its powerful purlin maker performance:

-

Product Range: 80–300mm (Covers a vast array of standard purlin sizes)

-

Working Speed: 12–15 meters per minute (without cutting/punching)

-

Roll Stations: 25 (Ensures smooth, accurate forming)

-

Roller Material: Cr12 steel, hardened to HRC 58-62 (Extreme wear resistance)

-

Main Shaft Material: 45# steel, 76mm diameter (Provides massive torque and rigidity)

-

Power: 15 kW (Delivers consistent power for high-volume output)

Essentially, the use of hardened Cr12 steel for rollers and solid 45# steel shafts means this steel purlin forming equipment resists wear and deflection. This durability ensures your machine maintains precision for years, even under heavy use.

Why Choose This Roll Forming Machine for Your Business?

Selecting the right C section roll forming line impacts your entire operation. Here’s why this model stands out:

-

Superior Flexibility: One machine produces many sizes, so you can take on more types of jobs without more machines.

-

Robust Construction: High-grade materials fight wear and tear, leading to lower long-term maintenance costs and less downtime.

-

High Output Speed: A speed of 12-15 m/min enables you to fulfill large orders quickly and improve your project turnaround time.

-

Proven Reliability: The design is based on proven engineering principles for cold roll forming machines, ensuring stable operation.

Key Applications in Construction and Industry

This automatic purlin machine is a workhorse for many sectors. Primarily, it serves metal building manufacturers and pre-engineered building (PEB) companies. Additionally, construction firms and roofing contractors use it to make custom components on-site or in their workshops. Basically, anyone who needs reliable, structural C-section steel will benefit from this machine’s output.

Investing in Quality and Support

When you invest in an 80-300 C purlin roll forming machine, you’re not just buying hardware. You’re securing a tool for business growth. We provide comprehensive support, from installation guidance to maintenance tips. Moreover, understanding the total cost of operation is easier with a durable, efficient machine that minimizes problems.

In conclusion, for dependable, high-volume production of structural C purlins, this 25-station machine is an exceptional choice. It combines flexibility, power, and precision in one robust package.

Contact us for more detailed specifications, pricing, and to discuss how this 80-300 C purlin roll forming machine can meet your specific production goals.