Garage door automatic cold roll forming machine technology represents the pinnacle of manufacturing efficiency for garage door production facilities. This advanced equipment transforms raw coil materials into precision garage door components with remarkable speed and accuracy, revolutionizing how manufacturers approach production timelines and quality control. The sophisticated engineering behind these machines ensures consistent output while significantly reducing labor costs and material waste.

The integration of automatic cold roll forming processes into garage door manufacturing has created unprecedented opportunities for businesses to scale their operations while maintaining strict quality standards. These specialized machines handle various materials including color steel and galvanized steel from 0.5mm to 1.2mm thickness, accommodating diverse design requirements and customer specifications with flexible production capabilities.

Unmatched Technical Specifications for Superior Performance

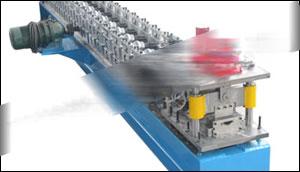

Our garage door automatic cold roll forming machine boasts engineering excellence through its comprehensive technical parameters. The machine accommodates variable coil widths based on customer profile requirements, ensuring perfect customization for specific garage door designs. With a working speed of 12-15 meters per minute (excluding cutting time), this equipment outperforms traditional manufacturing methods by substantial margins, delivering higher throughput without compromising precision.

The robust construction features 14 roll stations, each meticulously engineered to transform flat sheet metal into perfectly formed garage door components. According to the Precision Metalforming Association, multi-station roll forming systems significantly improve product consistency compared to single-stage forming processes, making our 14-station configuration ideal for high-volume garage door production environments where dimensional accuracy is paramount.

Premium Material Construction for Longevity

The durability of our garage door automatic cold roll forming machine begins with its superior material selection. All rollers are constructed from 45# forge steel, polished to exacting standards, and coated with chrome for exceptional wear resistance and prolonged service life. This material specification ensures consistent performance even under continuous operation, reducing maintenance requirements and downtime.

The main shaft utilizes 45# forge steel with a substantial diameter of 56mm, providing the structural integrity necessary to maintain precision under heavy production loads. This robust construction prevents deflection and ensures consistent profile formation throughout extended production runs, delivering reliable performance that manufacturers can depend on for their daily operations.

Advanced Cutting Technology for Precision Results

The cutting system integrated into our garage door automatic cold roll forming machine represents the forefront of manufacturing technology. Utilizing post-forming cutting methodology, the system processes sheets after roll forming to achieve required lengths with exceptional accuracy. The automated process sequence ensures optimal efficiency – the main machine automatically stops when cutting is required, then seamlessly resumes operation after the cutting cycle completes.

The cutting blades manufactured from CR12 material with specialized heat treatment maintain sharpness through extended use, reducing replacement frequency and ensuring clean, burr-free cuts. This attention to cutting component quality reflects our commitment to delivering comprehensive solutions that address every aspect of the garage door manufacturing process.

Precision Measurement and Tolerance Control

The integrated automatic length measuring system in our garage door automatic cold roll forming machine guarantees dimensional accuracy that meets the most stringent quality standards. With length tolerance maintained within ±1.5mm, manufacturers can achieve consistent results across production batches, eliminating fitting issues during garage door assembly and installation.

This precision measurement capability, combined with the machine’s consistent forming action, ensures that every garage door component meets specification requirements. The tight tolerance control significantly reduces material waste and rework costs, contributing to improved profitability while maintaining product quality that enhances brand reputation in competitive markets.

Power Transmission and Drive Systems

The power transmission system of our garage door automatic cold roll forming machine utilizes durable 1-inch chains to transfer motion reliably throughout the equipment. This robust transmission method ensures synchronized operation across all forming stations, maintaining consistent profile development from the first to the final station. The main power requirement of 4kW provides sufficient energy for continuous operation while maintaining energy efficiency—an important consideration in today’s cost-conscious manufacturing environments.

The chain drive system offers distinct advantages over alternative transmission methods, including higher torque capacity, better synchronization between stations, and reduced maintenance requirements compared to belt-driven systems. This engineering choice reflects our commitment to delivering equipment that performs reliably in demanding production settings.

Production Speed and Efficiency Analysis

The operational efficiency of our garage door automatic cold roll forming machine translates directly to improved manufacturing economics. With production speeds of 12-15 meters per minute, a single machine can output substantial linear footage of formed garage door components during a standard production shift. This high-speed capability, combined with minimal setup requirements, enables manufacturers to respond quickly to fluctuating market demands and custom orders.

When compared to traditional press brake forming methods, automatic cold roll forming demonstrates clear advantages in production volume, consistency, and operational cost. The Fabricators & Manufacturers Association notes that roll forming can be up to 40 times faster than press brake forming for long production runs, making it the ideal solution for garage door manufacturers supplying both residential and commercial markets.

Material Compatibility and Versatility

The versatility of our garage door automatic cold roll forming machine extends to its material compatibility, handling both color steel and galvanized steel within the 0.5mm to 1.2mm thickness range. This flexibility allows manufacturers to produce diverse product lines from the same equipment, adapting to market trends and customer preferences without capital investment in additional machinery.

The ability to process pre-finished materials like color steel represents a significant advantage, as formed components require no additional painting or surface treatment after forming. This capability streamlines the production process, reduces handling requirements, and delivers finished products with superior surface quality compared to post-forming finishing processes.

Operational Safety and Ease of Use

Despite its advanced capabilities, our garage door automatic cold roll forming machine prioritizes operator safety and intuitive operation. The integrated control systems monitor machine functions continuously, automatically stopping operation if irregularities are detected. This proactive approach to equipment safety protects both personnel and machinery, reducing the risk of accidents and minimizing potential damage to the equipment.

The automated nature of the machine reduces operator intervention requirements, allowing staff to focus on quality verification and material handling rather than direct machine operation. This operational approach not only enhances safety but also optimizes labor utilization, contributing to overall production efficiency.

Return on Investment Considerations

Investing in our garage door automatic cold roll forming machine delivers compelling financial returns through multiple channels. The increased production speed directly translates to higher output capacity without proportional increases in labor costs. The precision forming and cutting capabilities reduce material waste significantly, while the consistent quality output decreases rejection rates and associated costs.

The durability and reliability of the machine ensure years of consistent performance with minimal maintenance requirements, protecting the capital investment over an extended service life. For garage door manufacturers looking to expand capacity, improve product quality, or enter new market segments, this equipment represents a strategic investment that supports business growth objectives while strengthening competitive positioning.

Industry Applications and Customization Options

While specifically engineered for garage door production, our automatic cold roll forming machine adapts to various profile requirements within the building products sector. The flexible tooling approach allows for relatively quick profile changes, enabling manufacturers to produce different garage door styles and potentially diversify into related product lines such as architectural panels or building trim components.

The machine’s design accommodates custom tooling development for specialized profiles, providing manufacturers with opportunities to develop proprietary product designs that differentiate their offerings in the marketplace. This adaptability extends the equipment’s utility beyond standard production applications, supporting innovation and product development initiatives.