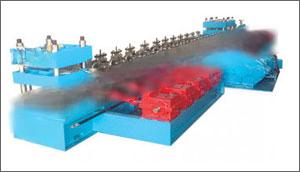

A guardrail roll forming machine is the cornerstone of modern safety infrastructure production. This specialized equipment transforms coils of raw steel into the strong, continuous profiles that become highway barriers, livestock fences, and critical perimeter security. The quality and reliability of the machine directly influence the performance and lifesaving capabilities of the final guardrail product. This article delves deep into the features, specifications, and critical advantages of a top-tier guardrail roll forming machine, providing you with the essential knowledge for making an informed investment.

Unmatched Production Characteristics and Uses

The design philosophy behind a high-performance guardrail roll forming machine prioritizes rigidity, stability, and automation. Unlike simpler machines, advanced models incorporate specific features to meet the demanding standards of safety-critical applications.

-

Enhanced Firmness with Multi-Station Design: Our machine utilizes a robust 12-station configuration. Each station progressively shapes the steel with precision, ensuring a consistent and structurally sound profile. This multi-stage process increases the final product’s firmness and dimensional accuracy, which is non-negotiable for components like highway guardrail systems that must withstand high-impact forces. The importance of this structural integrity is highlighted by the rigorous testing standards set by organizations like the American Association of State Highway and Transportation Officials (AASHTO).

-

Geared for Stability: Gearbox Transmission System: A key differentiator is the use of a gearbox transmission system. This method of drive is superior to alternatives, providing immense torque, reducing slippage, and ensuring that every forming roll moves in perfect synchronization. The result is a smoother, more stable operation with minimal vibration, which directly translates to a higher-quality steel guardrail with uniform geometry and superior surface finish.

-

Versatile Application Output: The true value of this metal forming machinery lies in its versatility. It is engineered to produce a variety of essential products:

-

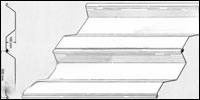

Highway Guardrail: The primary output, creating the W-beam or thrie-beam profiles that line our roads and highways.

-

General Safety Fencing: Used for industrial sites, public spaces, and other areas requiring secure perimeters.

-

Livestock Farm Fencing: Producing durable corrals and pens for agricultural use, demonstrating the machine’s adaptability beyond traffic safety.

-

Decoding the Main Technical Specifications

Understanding the technical data of a guardrail roll forming machine is crucial to ensuring it matches your production goals. Here is a detailed breakdown of the key specifications:

-

Material Thickness Capacity: 3-5 mm

This range indicates the machine is built for heavy-duty work. It can process thick, high-strength steel, which is mandatory for creating crashworthy road safety barriers that comply with federal and state regulations. -

Production Speed: 15 meters/minute (excluding cutting and punching)

This linear speed reflects a focus on controlled, quality-focused production. While speed is a factor, the priority is on maintaining the integrity of the profile. It’s important to note that this is the forming speed; the overall output will be influenced by the efficiency of the downstream cutting and punching operations. -

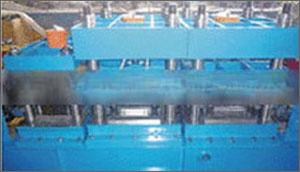

Roll Forming Stations: 12 Stations

The 12 stations are the heart of the machine. This number allows for a gradual and precise forming process, reducing stress on the material and ensuring the complex cross-section of a highway guardrail is achieved without distortion. More stations generally allow for the production of more complex and stronger profiles. -

Drive System: Gear Box or Chain

As mentioned, the gearbox drive is ideal for high-torque, stable operation. The option for a chain drive might be offered for different models or specific customer requirements, though a gearbox is typically preferred for heavy-gauge guardrail production. -

Control System: Panasonic PLC

The brain of the operation is a Panasonic Programmable Logic Controller (PLC). This industrial computer provides reliable, automated control over the entire process, including the roll forming speed, the cutting length, and the punching cycle. PLC control ensures repeatability, reduces human error, and allows for easy setup of different product parameters. For a deeper understanding of how PLCs revolutionize automation, you can refer to resources from ISA – The International Society of Automation. -

Power Requirements:

-

Main Power: 37KW: This substantial power rating drives the main forming motors, providing the necessary force to bend thick steel consistently.

-

Hydraulic Power: 18.5KW: This separate system powers the hydraulic units for auxiliary functions, most notably the precision punching of holes in the guardrail for subsequent assembly and installation.

-

Why Invest in This Advanced Guardrail Production Line?

Investing in this level of equipment is an investment in quality, efficiency, and reputation. The combination of a gearbox drive, multiple forming stations, and PLC control creates a reliable barrier manufacturing solution. It reduces downtime, minimizes material waste, and produces guardrails that you can trust to perform their safety function. Whether you are supplying to government transportation departments or agricultural developers, this machine provides the technological edge needed in a competitive market.

By choosing a machine with these specifications, you are not just buying a piece of equipment; you are acquiring a complete solution for producing the vital safety barriers that protect lives and property every day.