7 Powerful Reasons to Choose Our Advanced Highway Barrier Machine

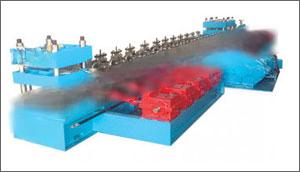

Highway barrier machines are engineering marvels designed for one critical purpose: producing the robust safety systems that protect motorists every day. Our state-of-the-art highway barrier roll forming machine is engineered for precision, durability, and high-volume output, making it the ideal choice for manufacturers supplying national infrastructure projects. This isn’t just a machine; it’s a commitment to public safety and manufacturing excellence.

Unmatched Production Characteristics and Uses

This highway barrier machine is built with innovations that set it apart from conventional models. It adopts a reinforced station design that significantly increases the structural firmness of the entire frame, ensuring consistent performance under continuous operational load. Unlike simpler systems, this machine utilizes a gearbox transmission system, which guarantees smoother power delivery and more stable operation, reducing vibration and material stress.

The primary use of this guardrail production equipment is to fabricate a variety of essential safety barriers, including:

-

Highway Guardrails: The main product, designed to meet strict national safety standards.

-

General Fencing: Adaptable for producing heavy-duty security and boundary fencing.

-

Livestock Farm Guards: Creating durable corrals and enclosures for agricultural use.

This versatility makes it a valuable asset for any metal fabrication business looking to diversify its product line.

In-Depth Look at Technical Superiority

Let’s break down the main technical specifications that contribute to this machine’s powerful performance:

-

Material Thickness (2.0-3.2mm): This range allows the machine to process a wide array of high-strength steel, enabling the production of highway safety barriers that can withstand significant impact forces as outlined in safety manuals from bodies like the Federal Highway Administration.

-

Production Speed (15 m/min): This impressive speed, which excludes the time for cutting and punching, ensures high throughput for large-scale infrastructure projects, maximizing your return on investment.

-

17 Roll Forming Stations: The high number of stations is a key feature. It allows for a gradual and precise forming process, which results in a superior product with consistent geometry and reduced internal stress, crucial for the reliability of a road guardrail.

-

Powerful Drive System (Main Power: 37KW, Hydraulic: 18.5KW): This robust power configuration handles the high torque demands of forming thick steel, ensuring the machine never struggles, even at maximum load.

-

Advanced Control System (Panasonic PLC): The heart of the machine. The Programmable Logic Controller (PLC) automates the entire process, from roll forming to cutting and punching, ensuring repeatable accuracy and reducing the potential for human error. Learn more about the role of PLCs in industrial automation from resources like ISA.

-

Gearbox or Chain Drive: This choice offers flexibility. The gearbox drive is ideal for the highest stability and power transmission, while a chain drive can be a cost-effective solution for certain applications.

Why Our Machine is the Smart Investment for Your Business

Investing in this highway barrier machine translates to tangible business benefits beyond just producing a product.

Enhanced Productivity and Efficiency

The combination of high speed, automated PLC control, and a stable gearbox drive means you can produce more linear meters of guardrail per shift. This efficiency directly boosts your profitability and allows you to meet tight project deadlines with confidence.

Superior Product Quality and Consistency

The 17-station forming process is critical. By gradually shaping the steel, it prevents material weaknesses and ensures every meter of guardrail produced has the exact same profile and strength characteristics. This consistency is non-negotiable in the safety infrastructure industry.

Remarkable Durability and Low Maintenance

The heavy-duty construction and use of a gearbox transmission are not just for performance; they are for longevity. These components are designed to withstand years of continuous operation with minimal downtime, protecting your investment far into the future. This industrial manufacturing machine is built to last.

Operational Safety and Ease of Use

Modern roll forming machines like this one are designed with operator safety in mind. The PLC system can integrate safety interlocks and monitoring. Furthermore, a well-designed machine is easier to operate and requires less specialized training, reducing operational costs.

Ready to elevate your manufacturing capabilities and contribute to safer roads? Contact our team of experts today to discuss how this advanced highway barrier machine can be integrated into your production line. Request a detailed quotation and technical data sheet to see the difference for yourself.