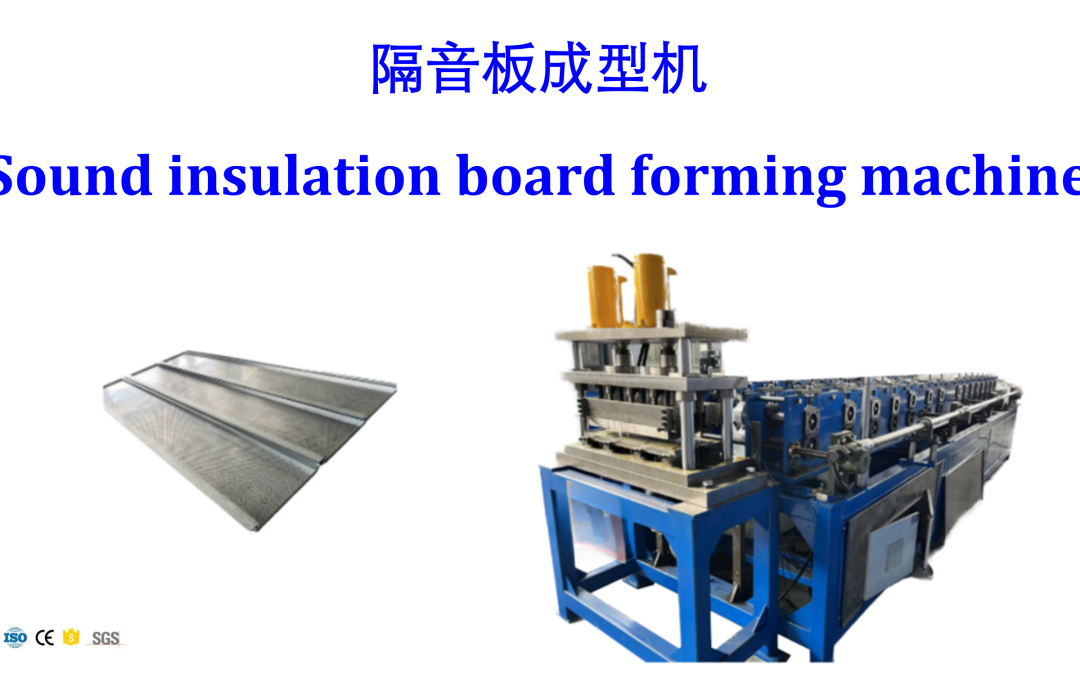

Sound Insulation Board Forming Machine: The Complete Guide to Custom Acoustic Panel Production

A sound insulation board forming machine represents specialized industrial equipment engineered for manufacturing noise reduction barriers used in highways, industrial facilities, and urban infrastructure. These custom roll forming systems transform metal coils into precise, durable profiles that form the structural core of acoustic panels. As global noise pollution regulations tighten—a concern highlighted by resources like the World Health Organization on environmental noise—the demand for efficient production of these barriers has never been higher. This guide explores everything you need to know about investing in a sound insulation board forming machine.

What is a Sound Insulation Board Forming Machine?

This machinery is a heavy-duty, cold roll forming line specifically designed to produce the metal framing and casings for soundproofing panels. Unlike standard roll formers, a sound insulation board forming machine must handle thicker materials (1.5-4mm) to create the robust structures required for outdoor, load-bearing applications like expressway barriers. The key to its value is customization; since different countries and projects mandate unique profiles, the machine is built to your exact specifications.

Why Customization is Non-Negotiable

The most critical aspect of this equipment is its bespoke design. “Different countries have different profiles,” meaning a one-size-fits-all approach fails. Whether you need profiles for T-shaped, inclined, or vertical noise barriers, a custom soundproof panel roll forming line ensures perfect dimensional accuracy for optimal acoustic performance and installation fit. This aligns with industry best practices for manufacturing, as noted by engineering resources such as ThomasNet on custom fabrication.

Detailed Technical Specifications & Performance Data

Understanding the robust specifications of a sound insulation board forming machine is crucial for evaluating its capability. Below are the standard parameters for a high-performance model:

Core Performance Metrics:

-

Working Speed: 10-15 meters per minute (shearing time excluded), balancing efficiency with precision for heavy-gauge material.

-

Pressed Plate Thickness: 1.5mm to 4mm, accommodating the structural demands of highway and industrial barriers.

-

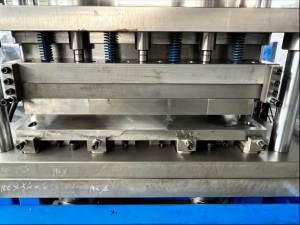

Number of Molding Passes: 23 stations (profile-dependent), ensuring smooth, accurate, and complex shape formation.

-

Length Tolerance: ±1.5mm for a 3-meter panel, guaranteeing consistency critical for seamless barrier installation.

Critical Component Specifications:

-

Roll Material: GCr15 bearing steel, precision-processed, quenched to HRC58-62, and chrome-plated for supreme wear resistance and longevity.

-

Shaft Material & Diameter: 45# steel finishing with a substantial shaft diameter of ¢100mm for unwavering stability.

-

Cutting (Shears) Material: Cr12MoV tool steel, quenched to HRC 58-62, for clean, durable cuts.

-

Transmission Mode: Gearbox drive, providing the high torque needed for thick plates.

Power & Control Systems:

-

Main Host Power: 30 KW

-

Hydraulic Station Power: 15 KW (Pressure: 16Mpa)

-

Control Mode: Panasonic PLC for reliable, automated, and repeatable operation.

-

Voltage: Standard 380V, 50HZ, 3-phase (customizable to client requirements).

Physical Layout & Logistics:

-

Equipment Form: Archway structure for enhanced stability.

-

Overall Dimensions (LxWxH): 15.5m x 1.6m x 1.2m.

-

Discharging Rack: 5-ton manual discharging rack.

-

Standard Delivery Time: 80 days from final design approval.

-

Payment Terms: Typically 30% advance, 70% upon delivery.

Key Applications: Where Are These Machines Used?

The primary product of this acoustic board production line is the metal component for:

-

Highway & Expressway Sound Barriers: The major application, reducing traffic noise for adjacent communities.

-

Industrial Noise Enclosures: Panels for factories and power plants to contain machinery noise.

-

Railway Noise Barriers: Mitigating noise from train lines.

-

Architectural Acoustic Partitions: For buildings requiring specialized sound management.

5 Vital Factors to Consider Before Purchasing

-

Profile Design Collaboration: Be prepared to provide detailed CAD drawings or samples of your required profile. The machine builder’s engineering team will design the roll forming machine around this.

-

Material Grade Compatibility: Confirm the machine is calibrated for your specific steel grade and yield strength within the 1.5-4mm range.

-

Automation & Control Level: The Panasonic PLC is standard, but discuss options for touchscreen interfaces, fault diagnostics, and length measurement systems.

-

After-Sales & Training: Ensure the supplier offers comprehensive installation supervision, operator training, and a ready supply of spare parts like the hardened GCr15 rollers.

-

Total Cost of Ownership: Look beyond the initial price. A machine with high-quality components like chrome-plated GCr15 rollers minimizes downtime and maintenance costs, offering better long-term value.

The Future of Noise Barrier Manufacturing

As urban expansion continues, the strategic importance of effective sound insulation grows. Investing in a dedicated, custom forming machine positions your business to meet this demand efficiently, producing high-quality barriers that comply with increasingly strict environmental and safety regulations.

Conclusion

A custom sound insulation board forming machine is a significant capital investment that unlocks the potential for large-scale, profitable production of essential noise control products. By focusing on customization, robust specifications, and reliable automation, you can select a production line that will serve as the backbone of your acoustic barrier manufacturing for years to come.

Contact us now.