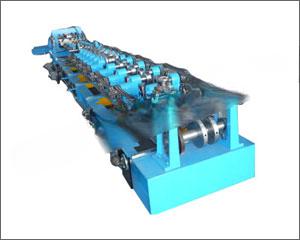

Powerful C&Z Purlin Interchangeable Forming Machine: The Ultimate 2-in-1 Solution

–cold roll forming machine

The C&Z purlin interchangeable forming machine represents a significant leap forward in the efficiency and flexibility of modern steel construction manufacturing. This innovative piece of equipment is engineered to solve a critical bottleneck in production: the need for separate, dedicated machines for different purlin profiles. By integrating the capability to produce both C and Z sections into a single, robust system, this machine drastically reduces downtime, saves on factory floor space, and enhances overall operational agility. For companies involved in pre-engineered buildings (PEB), warehouses, and industrial structures, investing in this technology is a strategic move toward greater profitability and competitive advantage.

Unlocking Unmatched Production Efficiency

The core value of the C&Z purlin interchangeable forming machine lies in its revolutionary design focused on maximizing uptime and simplifying complex production schedules.

Rapid Changeover and Profile Versatility

The most compelling feature of this purlin forming system is its ability to switch between producing C-section and Z-section purlins quickly. The conversion is achieved by exchanging the position of the forming rollers. Traditionally, this could take hours, but with this advanced machinery, the changeover is completed in approximately 30 minutes. This swift transition means your production line can respond immediately to project demands without significant delays, allowing for smaller, more economical batch runs and just-in-time manufacturing principles.

Precision and Automated Control

Precision is non-negotiable in structural components. This C and Z purlin equipment incorporates an automated system to adjust the horizontal distance between rollers. This ensures that both C and Z purlins are formed to exact width specifications with consistent, high-dimensional accuracy. This level of control, often managed by a sophisticated PLC (like the specified Panasonic system), eliminates human error and guarantees that every purlin produced meets strict quality standards, contributing to the overall integrity of the steel structures they support. You can learn more about the importance of precision in manufacturing from resources like the American Society of Mechanical Engineers (ASME).

In-Depth Technical Specifications

Understanding the robust capabilities of this machinery is key. Below are the detailed technical specifications that define its performance envelope.

-

Material Thickness: Handles a robust range from 1.5mm to 3.0mm, making it suitable for a wide array of structural applications.

-

Production Speed: Operates at an efficient speed of 15 meters per minute, ensuring a high and consistent output.

-

Forming Stations: Comprises 18 stations in total, which includes 7 dedicated straightening stations to ensure the final product is perfectly flat and straight.

-

Power Configuration:

-

Main Power: 19 KW

-

Hydraulic Power: 5.5 KW

-

-

Control & Drive System:

-

Control System: Utilizes a reliable Panasonic PLC for seamless automation and process control.

-

Drive Mechanism: Chain-driven for robust and reliable power transmission.

-

-

Automation Level: Available in both semi-automatic and fully automatic configurations to suit different production environments and investment levels.

Advanced Leveling and Punching Capabilities

A complete purlin fabrication machinery solution often includes integrated post-forming processes. Our systems can be equipped with high-precision leveling and punching units. The leveling unit ensures the final purlin is free of any camber or twist, which is critical for easy installation on-site. The punching unit can be customized to create precise holes for bolts, conduits, and other utilities as per your specific architectural and engineering drawings. This integration streamlines the production process, transforming raw coil steel into a finished, ready-to-install component in one continuous operation.

Customization: Tailored to Your Production Needs

We recognize that every manufacturer has unique requirements. Therefore, our C&Z purlin interchangeable forming machine is not a one-size-fits-all product. We offer extensive customization options to ensure the machine aligns perfectly with your operational goals. Whether you need to adjust the machine for a specific material grade, a unique thickness outside the standard range, or a special purlin profile design, our engineering team can collaborate with you. By providing your custom designs, material specifications, and other requirements, we can design and build a machine that is uniquely yours. The National Institute of Standards and Technology (NIST) provides frameworks for manufacturing standards that often inform these custom engineering solutions.

Why Choose Our C&Z Purlin Forming System?

Investing in our purlin forming system is an investment in the future of your manufacturing capability. The benefits are clear and impactful:

-

Dual-Functionality: One machine replaces two, saving significant capital investment and factory space.

-

Minimized Downtime: The 30-minute changeover dramatically increases production flexibility and asset utilization.

-

Superior Precision: Automated controls and multiple forming stations guarantee high-quality, consistent output.

-

Enhanced Profitability: Reduced downtime, lower labor costs, and increased throughput directly contribute to a stronger bottom line.

-

Future-Proof Design: The customizable nature of the machine ensures it can adapt to your evolving business needs.

In conclusion, the C&Z purlin interchangeable forming machine is more than just a piece of equipment; it is a comprehensive production solution designed for the dynamic demands of the modern construction industry. Its versatility, speed, and precision make it an indispensable asset for any serious player in the steel framing sector.

Contact us now.