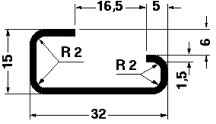

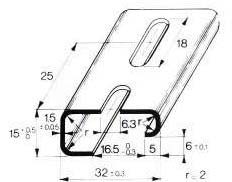

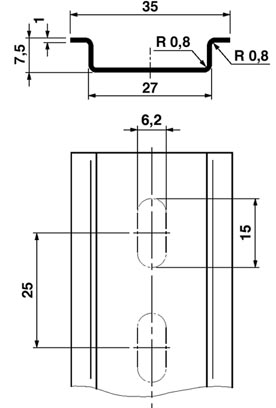

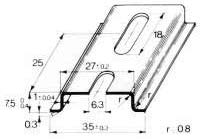

C G STEEL PANEL PROFILE

— C G cold roll forming machine

This is C profile steel panel and G profile steel panel roll forming making machine.

Client requirments

Material thickness:1.5mm

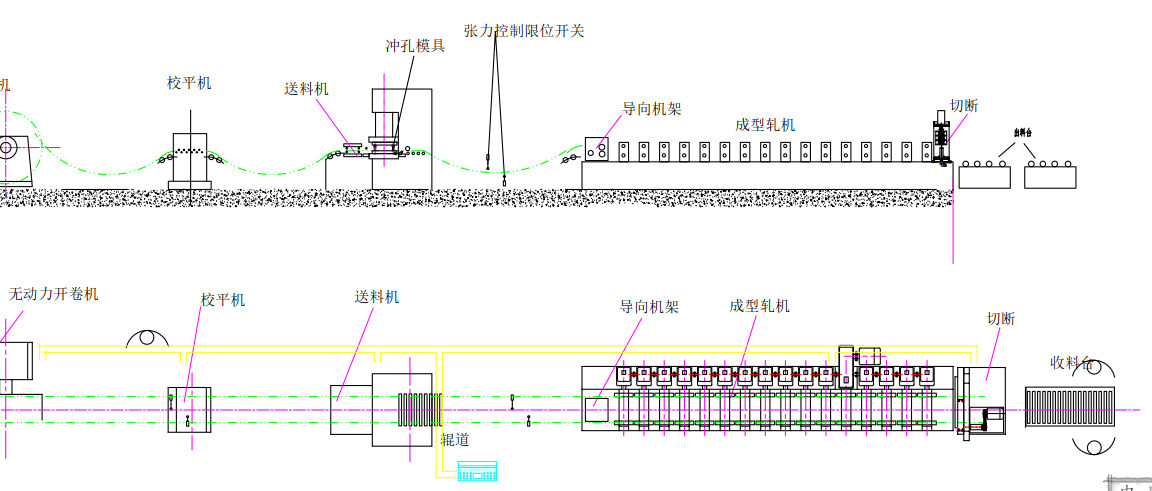

A: Equipment flow chart

B: Equipment working flow

Load-uncoil(send the steel into the 1st roll of the main machine)-flat the CR strips-punching-roll forming-hydraulic cutted-products

C: Equipment components

1.uncoiler

single uncoiler, load on one side

Max CR strips weight: 2000Kg

Max CR strips diameter: 1200mm

Max CR strips width: 250mm

2.loading, flatting

uncoil into guide roll(adjust on both sides)

into loading rolls, ¢100mm,material 45# steel, quench 48°-52°, chromeplate

flatting:three roll UP,four rolls down,surface quench and chromeplate.

flatting power:5.5KW

Speed: 5-20m

3.servo punching

servo power: 3KW

speed;30m/min

precision:+/-0.1MM

punching

punching weight:40t

punching frequence: 30times/min

mould material: Cr12,quenching to 58°-62°

4.roll forming, adjustment, cut

main power: 5.5KW

cycloidal reducer: BWD14-43-5.5KW

transmission: chain

Main shaft diameter:¢65mm,45#

Roller material: GCR15 quench to 58°-62°, chromeplate

Roller groups:14 extra 3rolls for adjustment

transducer : Panasonic(380V,50HZ)

PLC control:Panasonic

Operation panel: touching screen

Encoder: OMRON

Cutting method: hydraulic pressure

Blade material: Cr12, quenching to 58°-62°

Oilcan diameter:80mm

Working pressure:12mpa

Working journey: 80mm

6.Equipment Size:

Long: 25m*Width: 2m*Height: 1.5m

7.discharger

- 60m*40m square tube jointing

- Size: Long:1.5m*Width: 0.8m*Height:1m

D: Equipemnt Parts

1: uncoiler 2T 1PC

2: flatting feed 1PC

3: Servo feed 1PC

4: Punching mould 2SETS

5: Punching 40T 1PC

6: Roll Forming Machine 1PC

7: Hydraulic cutting 1PC(include 4blades)

8: Hydraulic station 1PC

9: Control Box 4PCS(1;uncoil 2;flatting 3;feeding 4;forming)

10: Discharge 2PCS

E: Terms

Delivery: 90days after receive 30% deposit by T/T

Payment: deposit 30% T/T, 70%T/T before shipment

Guarantee: 1year, lifecycle technical guide service