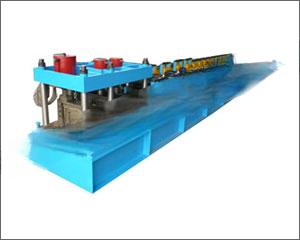

Revolutionary C Purlin Roll Forming Machine: The Ultimate 5-Station Powerhouse

C Purlin Roll Forming Machines are the bedrock of efficient and profitable metal construction manufacturing. For contractors, steel fabricators, and building suppliers, selecting the right equipment is the single most important decision impacting output quality, project timelines, and bottom-line profitability. This comprehensive guide delves into why our state-of-the-art C Purlin Roll Forming Machine is a revolutionary leap forward, designed not just to meet but to exceed the demands of modern construction.

What is a C Purlin Roll Forming Machine?

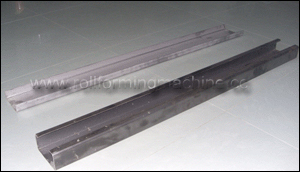

A C Purlin Roll Forming Machine is a highly specialized piece of industrial equipment that transforms flat coils of sheet metal into consistent, high-strength C-shaped purlins and girts. This is achieved through a cold-forming process where the metal strip is progressively shaped by a series of meticulously engineered roller dies. The result is a continuous, high-speed production line for essential structural components. These C sections are indispensable in constructing roofs and walls for pre-engineered buildings, warehouses, industrial facilities, and agricultural sheds. The precision of this C Section Forming System ensures every component is identical, eliminating costly on-site fitting errors. For foundational knowledge on steel construction, the American Institute of Steel Construction is an excellent resource.

5 Revolutionary Benefits of Our C Purlin Roll Forming Machine

What makes our C Purlin Roll Forming Machine the definitive choice for industry leaders? The answer is a combination of robust engineering and intelligent design features that deliver tangible benefits.

-

Unrivaled Precision and Flawless Consistency: Each purlin produced is a perfect replica of the last, with exact dimensional accuracy and a clean, professional finish. This precision streamlines the entire construction process, drastically reducing labor time and material waste caused by fitting imperfect components.

-

Blazing Production Speed and Unmatched Efficiency: Operating at speeds up to 15 meters per minute, our machine supercharges your production output. This high-velocity capability empowers you to accept larger projects and confidently meet the most aggressive deadlines, giving you a significant competitive advantage.

-

Exceptionally Robust and Durable Construction: We have engineered our machine with reinforced stations and a heavy-duty frame to guarantee maximum firmness and long-term reliability. This robust build minimizes operational vibration, reduces maintenance downtime, and ensures a prolonged service life, even under the most strenuous production schedules.

-

Superior Cut Quality with Advanced Post-Cut Technology: Our machine employs a sophisticated after-cutting system. The metal is fully formed into its final C-shape before being cut, resulting in impeccably smooth, burr-free ends. This eliminates the need for secondary finishing processes, saving both time and money.

-

Flexible and Powerful Drive System Options: Catering to diverse production needs, we offer models with either a high-torque gearbox transmission or a resilient chain drive system. The gearbox provides exceptionally smooth and stable operation for heavy-gauge materials, while the chain drive offers a robust and cost-effective solution for a wide range of applications. The Society of Manufacturing Engineers SME offers insights into modern manufacturing technologies like these.

In-Depth Technical Specifications of Our C Purlin Machine

Understanding the core technical data is key to appreciating the capability of our C Purlin Roll Forming Machine. Our systems are built to handle rigorous industrial demands day in and day out.

Model: High-Performance C Purlin Machine

-

Material Thickness: 1.5mm – 3.0mm

-

Linear Production Speed: ~15 meters per minute (Cutting & punching time not included)

-

Number of Forming Stations: 18 Stations

-

Main Motor Power: 15 kW

-

Hydraulic Station Power: 5.5 kW

-

Control System: Panasonic PLC (Programmable Logic Controller) for reliable, automated control

-

Degree of Automation: Semi-Automatic / Fully Automatic

We provide two primary drive configurations to suit specific operational and budgetary requirements:

-

Gearbox Drive Model: Ideal for continuous, high-load production, this configuration delivers superior power transmission and remarkably smooth operation.

-

Chain Drive Model: A tremendously reliable and economical transmission solution that provides consistent performance for a vast array of manufacturing environments.

Versatile Applications in Modern Construction and Beyond

The components produced by this Purlin Manufacturing Line are critical to a multitude of structures. Its primary applications span the entire construction industry:

-

Pre-Engineered Buildings (PEBs): Forming the essential skeleton for roof and wall support systems.

-

Industrial and Commercial Structures: Including warehouses, factories, and large-scale retail sheds where long-span, lightweight support is crucial.

-

Agricultural Buildings: Such as barns, storage silos, and equipment sheds that require a strong, cost-effective framework.

-

Solar Panel Mounting Structures: The machine can be calibrated to produce specific C purlin profiles designed for robust solar array support systems.

-

Internal Framing and Mezzanine Floors: Used for creating secondary support structures within larger buildings.

Choosing the Right C Purlin Machine for Your Business

Selecting the ideal C Purlin Roll Forming Machine is a strategic decision. Key considerations include your target production volume, the range of material thicknesses you work with, and your desired level of automation. Our technical experts are ready to assist you in navigating these choices, ensuring you select a machine that perfectly aligns with your business objectives and maximizes your return on investment.

Whether you are scaling an existing operation or launching a new fabrication venture, our C Purlin Roll Forming Machine is engineered to be the most reliable and productive asset in your workshop, driving your growth for years to come.

Ready to transform your production capabilities? Contact us today to request a detailed quotation, a comprehensive technical datasheet, or to schedule a live demonstration with our engineering team. Let’s build the future, together.