Powerful Corrugated Roll Forming Machine: 3 Models for Ultimate Efficiency

— China roll forming machine supplier

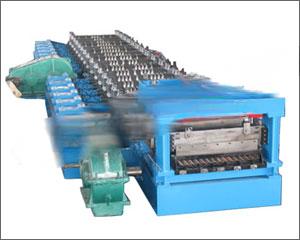

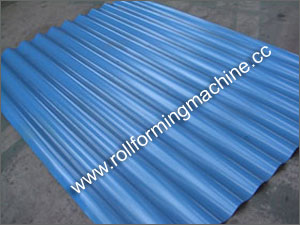

A corrugated roll forming machine is the cornerstone of modern metal fabrication for construction and industrial applications. This highly efficient equipment transforms flat sheets of metal into strong, consistent corrugated profiles used in roofing, siding, and structural panels. Investing in the right corrugated roll forming machine is crucial for maximizing output, maintaining quality, and staying competitive. Our machines are engineered for reliability and high performance, capable of processing a wide range of material thicknesses at impressive speeds. As a trusted agent and manufacturer with years of expertise in cold roll forming technology, we provide end-to-end solutions from design to shipping for clients worldwide.

What is a Corrugated Roll Forming Machine and How Does It Benefit You?

A corrugated roll forming machine is a specialized piece of industrial equipment that progressively shapes metal coils or sheets into a corrugated pattern through a series of paired rolls. Each set of rolls, or stations, incrementally bends the metal until the final, precise profile is achieved. This continuous process is ideal for high-volume production runs, offering significant advantages over alternative methods.

Key Advantages of Our Advanced Corrugated Roll Forming Machine

Our corrugated roll forming machines are designed with the user in mind, incorporating features that drive productivity and profitability.

-

High Production Efficiency: With working speeds of up to 30 meters per minute, our machines dramatically increase your output. This allows you to meet large orders and tight deadlines with ease, making your entire operation more streamlined and profitable.

-

Exceptional Versatility: Whether you are producing simple roofing for residential houses, heavy-duty panels for steel plants, or specialized wall boards, our range of machines can handle it. They process material thicknesses from a delicate 0.3mm all the way up to a robust 4mm.

-

Superior Consistency and Quality: The precision-engineered roll stations and advanced drive systems ensure that every meter of produced sheet has identical dimensions and a perfect profile. This eliminates waste and guarantees that your final products meet the highest quality standards.

-

Automation and Ease of Use: Featuring advanced Panasonic PLC control systems, our corrugated roll forming machines are simple to operate and monitor. Automation reduces the potential for human error and minimizes the need for extensive operator training, leading to a more stable production process. For a deeper understanding of industrial control systems, you can visit Panasonic’s Industrial Automation website.

Explore Our 3 Powerful Corrugated Roll Forming Machine Models

We offer a range of models to suit different production requirements and budgets. Each machine is built with durability and performance as a core focus.

Model A: The Standard Workhorse

-

Material Thickness: 0.3 – 0.8 mm

-

Working Speed: 12 – 15 m/min

-

Roll Stations: 18 stations (can be customized based on the profile)

-

Main Power: 5.5 KW

-

Hydraulic Power: 3 KW

-

Control System: Panasonic PLC

-

Drive System: Chain Drive

-

Ideal For: Small to medium-sized operations focused on standard roofing and siding sheets.

Model B: The High-Speed Performer

-

Material Thickness: 0.3 – 0.8 mm

-

Working Speed: 25 – 30 m/min

-

Roll Stations: 18 stations (can be customized based on the profile)

-

Main Power: 7.5 KW

-

Hydraulic Power: 3 KW

-

Control System: Panasonic PLC

-

Drive System: Chain Drive

-

Ideal For: Businesses that need to maximize output for high-volume orders of thinner gauge materials.

Model C: The Heavy-Duty Specialist

-

Material Thickness: 2 – 4 mm

-

Working Speed: 15 m/min

-

Roll Stations: 18 stations (can be customized based on the profile)

-

Main Power: 37 KW

-

Hydraulic Power: 7.5 KW

-

Control System: Panasonic PLC

-

Drive System: Gear Box Drive

-

Ideal For: Processing thick, structural steel plates for industrial buildings and heavy-duty applications where power and durability are paramount.

Choosing the Right Corrugated Roll Forming Machine for Your Needs

Selecting the correct model depends on your specific production goals. Consider the following:

-

Primary Material Thickness: If you work primarily with sub-1mm sheets, Model B offers unparalleled speed. For thicker materials, Model C is essential.

-

Required Output Volume: Model A is a cost-effective solution for moderate volumes, while Model B is designed for mass production.

-

Profile Complexity: The number of roll stations can be adjusted to create simple or complex corrugated profiles. We can customize the metal profile rolling machine to your exact specifications.

Why Partner With Us for Your Corrugated Roll Forming Machine?

With many years of experience in the cold roll forming machine market, we are more than just a manufacturer; we are your strategic partner. Our expertise allows us to provide comprehensive services, including custom machine design, precision production, and seamless worldwide shipping. We are committed to ensuring our corrugated roll forming machine integrates perfectly into your workflow.

We combine competitive pricing with exceptional customer service, offering ongoing support to keep your operations running smoothly. Our goal is to provide you with a corrugated roll forming machine that becomes a valuable, long-term asset to your business.

Ready to revolutionize your sheet metal production? Contact us today to discuss your requirements, request a detailed quotation, and discover how our powerful corrugated roll forming machines can drive your success.