Powerful Crimple Curve Roll Forming Machine: 5 Key Features for Superior Metal Bending

— cold roll forming machine supplier from China

Crimple Curve roll forming machine technology represents a significant leap forward in the metal fabrication industry, offering unparalleled precision, speed, and consistency in producing complex profiles. This machine is specifically engineered to transform flat sheet metal into consistent, high-quality “crimple curve” profiles, which are essential in various architectural, roofing, and cladding applications. For manufacturers seeking to enhance their production capabilities, understanding the advanced specifications and benefits of this specialized equipment is crucial. This in-depth guide will explore the technical prowess of this machine and why it is a vital asset for modern metalworking facilities.

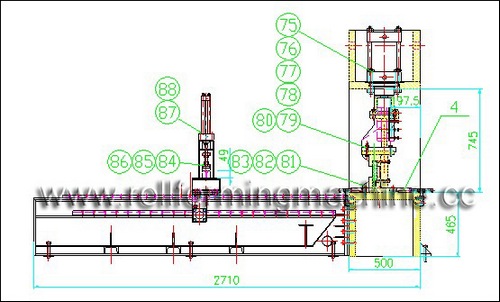

Unpacking the Crimple Curve Roll Forming Machine

At its core, a Crimple Curve roll forming machine is a continuous bending operation where sheet metal is passed through a series of mated rolls (or dies), each set performing an incremental part of the bend until the desired cross-sectional profile is achieved. Unlike press braking, which forms discrete parts, roll forming is a high-volume, continuous process ideal for creating long, consistent sections with complex geometries like the crimple curve. This method, as outlined by the Fabricators & Manufacturers Association, Intl. (FMA), is renowned for its efficiency and high repeatability [Link to: https://www.fmamfg.org/].

Our specific model is designed with a robust focus on reliability, precision, and user-friendly operation, making it a cornerstone for businesses looking to optimize their production lines.

Detailed Technical Specifications and Their Impact

The performance of any industrial machinery is defined by its technical specifications. Here’s a breakdown of the key specs for our Crimple Curve roll forming machine and what they mean for your operation:

Power and Drive Systems

-

Main Power: 0.85KW & Hydraulic Station Power: 5.5KW: This power distribution indicates a highly efficient system. The low main power consumption for the drive mechanism highlights energy efficiency, while the dedicated 5.5KW hydraulic station provides the substantial force required for consistent and powerful metal forming without straining the main motor.

-

Servo-actuator power: 1KW (Yaskawa): The integration of a Yaskawa servo actuator is a mark of high precision. Servo systems provide exceptional control over position and speed, which is critical for achieving accurate bends and repeatable profiles with every cycle.

Control and Precision Engineering

-

Control System: Mitsubishi brand PLC & Transducer Control (Panasonic): This is the brain of the operation. Using a Mitsubishi Programmable Logic Controller (PLC) ensures rock-solid reliability and sophisticated control over the entire roll forming system. Paired with Panasonic transducer control, the machine can make micro-adjustments on the fly, guaranteeing that every meter of produced profile meets exact specifications.

-

Working Speed: 0-10m/min: The variable speed control is a critical feature. Operators can start at a slow speed for setup and calibration and then ramp up to the full 10m/min for maximum throughput. This flexibility allows the machine to handle different material grades and thicknesses optimally.

Forming Capabilities

-

Max Bending Angle: 120°: This specification defines the machine’s geometric capability. A maximum bending angle of 120 degrees allows for the creation of highly complex and acute profiles, expanding the range of architectural and industrial applications for the finished product.

The Tangible Benefits of Advanced Roll Forming

Investing in a high-specification Crimple Curve roll forming machine translates into direct competitive advantages for your business.

-

Exceptional Consistency and Quality: The combination of the Mitsubishi PLC and servo-driven actuators ensures that every profile produced is identical. This eliminates product variation and reduces waste, leading to higher customer satisfaction and lower material costs.

-

Increased Production Throughput: With a working speed of up to 10 meters per minute, this metal bending machine can significantly outpace traditional forming methods. This high-speed production is essential for meeting large-order deadlines and improving overall plant productivity.

-

Reduced Operational Costs: The energy-efficient design and highly automated process minimize the need for manual intervention. This lowers labor costs and reduces the potential for human error, leading to a more streamlined and cost-effective operation over time.

-

Enhanced Flexibility: While designed for the crimple curve profile, a well-engineered roll forming system can often be retooled or adjusted for other similar profiles, providing your business with the agility to take on a wider range of projects.

Ideal Applications for the Crimple Curve Profile

The profiles produced by this machine are vital in several industries:

-

Architectural Roofing and Cladding: The crimple curve profile adds structural rigidity and a distinctive aesthetic to building exteriors.

-

Industrial Partitioning and Wall Systems: Used in factories and warehouses for durable, long-lasting walls.

-

Specialty Automotive and Transportation: For creating custom body panels and interior components.

For more on the science of metal forming, the American Society of Mechanical Engineers (ASME) provides extensive resources on the principles involved [Link to: https://www.asme.org/].

Why Partner With Us?

Choosing the right machinery partner is as important as the machine itself. We don’t just sell equipment; we provide production solutions. Our expertise in metal profile production machines ensures you get the support, training, and service needed to integrate this technology seamlessly into your workflow. From installation to preventative maintenance, our team is dedicated to maximizing your return on investment.

Conclusion

In a competitive manufacturing landscape, efficiency, precision, and reliability are non-negotiable. Our advanced Crimple Curve roll forming machine, with its superior control systems, powerful drive, and versatile forming capabilities, is engineered to deliver on all three fronts. It is more than just a piece of factory equipment; it is a strategic investment in the quality and scalability of your metal fabrication output.

Contact us now.