The Double Layer Roofing Wall Panel Roll Forming Machine is a cornerstone of modern construction material manufacturing, engineered for unparalleled efficiency and output quality. This advanced system is designed to transform raw steel coils into high-strength, precisely formed double-layer panels in a single, continuous operation. With robust features like 18 upper and lower stations, a powerful 5.5kW drive, and precision PLC control, this machine is built to meet the high-volume demands of the construction industry while maintaining exceptional tolerance standards of +/-1.5mm. This double layer roll forming machine is the ultimate solution for manufacturers aiming to enhance their production capabilities and dominate the market with reliable, high-quality building components.

Unpacking the Core Specifications: A Machine Built for Performance

To understand its capability, let’s delve into the key parameters that make this Double Layer Roofing Wall Panel Roll Forming Machine a powerhouse.

-

Product Spec.: 1200mm – Ideal for producing wide-format panels for extensive roof and wall coverage.

-

Working Speed: 12-15 meters per minute – This high-speed operation ensures maximum throughput and productivity for your factory.

-

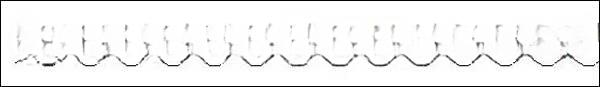

Roller Stations: 18 up, 18 down (36 total) – The high number of stations allows for a complex and precise forming process, resulting in a structurally superior double layer panel with a perfect interlock.

-

Roller Material: 45# forge steel, CNC machined, chromed (0.05mm) – This ensures extreme durability, wear resistance, and a long operational lifespan, reducing maintenance costs and downtime.

-

Control System: Panasonic PLC – The brain of the operation, guaranteeing consistent, automated, and error-free production cycles.

The Critical Advantage of the Double-Layer Design

What truly sets this equipment apart is its ability to produce double-layer panels. But why is this feature so revolutionary?

Unmatched Structural Integrity and Insulation

A double layer roofing and wall panel is not just two sheets of metal. It is an engineered product that creates a closed air gap between the two layers. This gap acts as a highly effective thermal break, significantly improving the insulation properties of the building envelope. This leads to reduced energy costs for heating and cooling, a key consideration in sustainable building design as highlighted by resources from the U.S. Green Building Council (USGBC). Structurally, this design creates a incredibly rigid panel that can withstand heavier snow loads, wind pressures, and physical impacts far better than single-skin alternatives.

Production Efficiency and Versatility

This specialized roll forming machine consolidates what would typically be multiple manufacturing steps into one seamless process. It forms both the inner and outer layers simultaneously, slashing production time and labor costs. Furthermore, the machine can be tooled to produce a variety of profiles, making it a versatile asset for a factory serving diverse architectural and industrial client needs.

In-Depth Look at Machine Components and Quality

The devil is in the details, and every component of this machine is selected for reliability.

The Heart of the Machine: The Roll Forming Stations

The 36 stations of hardened and chromed rollers are the core of the forming process. Each set of rollers gradually shapes the flat steel strip into the final roofing panel profile with immense precision. The use of 45# forged steel and a chrome surface finish ensures that the rollers can handle the abrasive nature of coated steel coils (0.3mm to 0.7mm thick) over a long service life without degrading the quality of the formed panel.

Precision Control and Drive Systems

The integration of a Panasonic PLC (Programmable Logic Controller) provides complete automation and control. This system manages the cutting length, production speed, and fault diagnostics, ensuring consistent quality across every panel. The 1-inch single chain drive, coupled with the 5.5kW main motor, delivers the smooth, powerful, and reliable transmission of force needed for continuous high-speed operation. The hydraulic system (4kW, 12Mpa) provides the necessary power for auxiliary functions like precise cutting with the durable Cr12Mov blades.

Applications and Benefits for Your Business

Investing in this Double Layer Roofing Wall Panel Roll Forming Machine translates into direct competitive advantages.

-

Wide-Ranging Applications: The panels produced are perfect for industrial warehouses, commercial buildings, agricultural facilities, cold storage, and modern architectural projects requiring high performance.

-

Superior Output Quality: Achieve consistent panel geometry, clean cuts, and a flawless surface finish that enhances the final building’s appearance and durability.

-

Increased Profitability: High-speed production and automated controls minimize labor requirements and raw material waste, directly boosting your bottom line.

-

Enhanced Market Position: By offering a premium, insulated double layer panel, you can access higher-value projects and differentiate yourself from competitors using older, less capable machinery. The Precision Metalforming Association is a great resource for industry standards and trends that can inform your business strategy.

Why Choose Our Roll Forming Machine?

We are a trusted manufacturer of high-end metal forming solutions. Our Double Layer Roofing Wall Panel Roll Forming Machine is the product of extensive engineering and a deep understanding of the construction industry’s needs. We don’t just sell a machine; we provide a production solution backed by robust technical support, comprehensive training, and readily available spare parts.

Ready to revolutionize your panel production line?

Our Double Layer Roofing Wall Panel Roll Forming Machine is engineered for durability, precision, and maximum return on investment.

[Contact Us Today] for a detailed quotation and to discuss how this advanced machine can meet your specific production goals. Let’s build the future of construction, together.