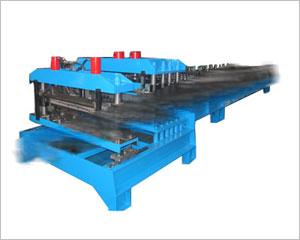

The Ultimate Guide to Our Powerful Steel Tile Roll Forming Machine

The Steel Tile Roll Forming Machine is a cornerstone of modern industrial manufacturing, transforming raw steel coils into precise, durable roofing profiles with remarkable efficiency. For businesses seeking to enhance their production capabilities, our state-of-the-art Steel Tile Roll Forming Machine with a unique double-press model sets a new standard for reliability, speed, and output quality. This machine is engineered to meet the high demands of contemporary construction, producing aesthetically pleasing and structurally sound roofing tiles for a wide range of architectural projects.

What is a Steel Tile Roll Forming Machine?

A Steel Tile Roll Forming Machine is a specialized piece of industrial equipment that continuously shapes flat sheet metal into specific, consistent profiles through a series of rotating rolls. Unlike single-strike pressing, the roll forming process creates a uniform product with a high-quality finish and minimal material stress. Our double-press model enhances this further by incorporating two pressing stations that work in tandem to ensure exceptional profile definition and material solidity. This process is fundamental in the metalworking industry, and you can learn more about its principles from resources like the Fabricators & Manufacturers Association, Intl..

Unmatched Advantages of Our Double-Press Model

Why should you choose our specific model? The benefits are clear and impactful:

-

Superior Structural Integrity: The integrated double-press system significantly increases the solidity of the final product. This results in steel roofing tiles that are more durable, resistant to environmental stress, and have a longer lifespan.

-

Enhanced Production Speed & Efficiency: With a forming speed of 5-6 meters per minute, this metal roll forming equipment maximizes output without sacrificing quality, allowing you to meet tight deadlines and large-volume orders.

-

Impeccable Aesthetic Quality: The precision of the 16-station roll forming process ensures every tile produced has a clean, sharp, and consistent profile. This enhances the visual appeal of any building, adding to modern architectural aesthetics.

-

Unwavering Consistency: Thanks to the advanced Panasonic PLC control system, every tile produced is identical. This eliminates production variances and ensures a perfect fit during installation on the roofing structure.

In-Depth Technical Specifications

Understanding the machine’s capabilities is key. Here are the core specifications that power its performance:

-

Material Thickness: Handles a versatile range from 0.3mm to 0.8mm steel, providing flexibility for different project requirements.

-

Forming Speed: A consistent and efficient speed of 5-6 meters per minute.

-

Roll Stations: 16 robust stations (quantity may be adjusted based on the specific profile design) ensure precise and gradual forming.

-

Drive System: A reliable chain drive mechanism powers the entire machine for smooth operation.

-

Control System: A fully automated Panasonic PLC ensures precise control, easy operation, and troubleshooting.

-

Power Configuration:

-

Main Power: 4.4KW Servo Motor for high torque and accuracy.

-

Hydraulic Power: 4KW power unit for the double-press system.

-

Core Production Characteristics and Applications

This steel tile forming machine is designed with practicality and performance in mind. The reinforced stations, a key feature of the double-press model, are built to withstand continuous operation, reducing maintenance downtime and increasing overall machine longevity.

The products manufactured by this machine are primarily used in modern architecture for roofing solutions. The high-quality roofing tiles produced not only provide excellent weather protection but also significantly boost the building’s aesthetics, offering a sleek, professional finish that is highly sought after in both commercial and residential construction.

Why the Double-Press Design is a Game-Changer

The “double-press” mechanism is the heart of this machine’s advantage. While a standard machine might use a single final press, our model incorporates two strategic pressing actions. This ensures the steel profile is perfectly set and work-hardened at critical points in the forming process. The result is a final product with unparalleled rigidity and dimensional accuracy, reducing the chance of spring-back or deformation in the field. This makes our tile roll forming machine particularly effective for producing complex profiles that require high structural stability.

Choosing the Right Machine for Your Business

Investing in a Steel Tile Roll Forming Machine is a significant step toward automating and scaling your production. When selecting a machine, consider your primary material thickness, desired output speed, and the complexity of the profiles you wish to produce. Our double-press model is ideally suited for manufacturers who prioritize top-tier quality and durability in their roofing products and aim to establish a reputation for excellence in the construction market.

Ready to revolutionize your roofing tile production? Contact us today to learn more about how our advanced Steel Tile Roll Forming Machine can drive your business forward.