Down pipe shaping and bending cold roll forming machines represent the pinnacle of manufacturing efficiency for metal pipe production. These sophisticated systems transform flat metal coils into perfectly formed pipes through a cold-forming process that maintains material integrity while achieving precise dimensions. As industry demands for standardized drainage systems, HVAC components, and structural piping increase, the need for reliable down pipe shaping and bending equipment becomes critical for manufacturers worldwide.

What is a Down Pipe Shaping and Bending Cold Roll Forming Machine?

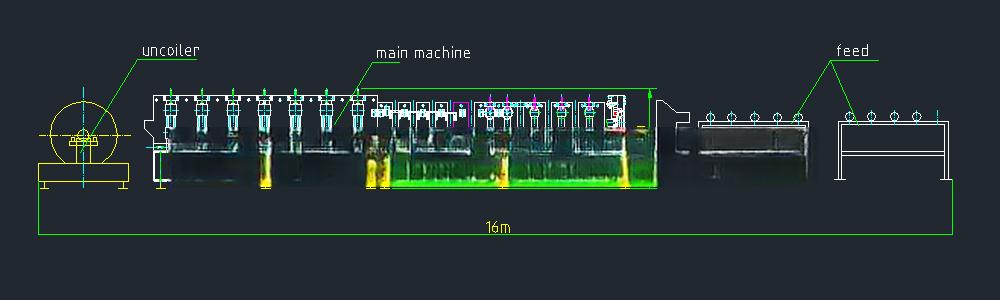

A down pipe shaping and bending cold roll forming machine is specialized industrial equipment designed to continuously shape metal strips into pipes through a series of roller stations. Unlike hot forming processes, cold roll forming works at room temperature, preserving the metal’s structural properties while creating consistent, high-quality products. The “down pipe” designation specifically refers to vertical drainage pipes used in building construction, though these machines can produce various pipe types for multiple applications.

Key Technical Specifications

Our advanced down pipe cold roll forming system features comprehensive specifications ensuring maximum performance:

Forming Section:

-

Main Power: 3kW hydraulic system

-

Forming Speed: 0-10mm/min (variable control)

-

Stations: 19 precision roller stations

-

Material Compatibility: 0.5-0.6mm color steel panels

-

Roller Material: 45# high-grade steel

-

Machine Dimensions: 7000mm × 1000mm × 1100mm

Bending Section:

-

Power: 2.2kW dedicated motor

-

Maximum Bend: 90-degree capability

-

Bending Speed: 20-25m/min

-

Section Dimensions: 1300mm × 650mm × 1500mm

The 5-Stage Manufacturing Process

-

Uncoiling: Metal coils are loaded and straightened for consistent feeding

-

Feeding: Precision feeding mechanisms ensure accurate material advancement

-

Roll Forming: 19 sequential stations gradually shape the metal into pipe form

-

Pressing/Hydraulic: 5.5kW hydraulic system secures form and connections

-

Cutting: PLC-controlled cutting produces exact pipe lengths

PLC Control System Advantages

The Programmable Logic Controller (PLC) represents the brain of our down pipe shaping machine. This advanced control system offers:

-

Precision speed regulation (0-10mm/min forming, 20-25m/min bending)

-

Automated cutting coordination

-

Error detection and safety protocols

-

Production data tracking and reporting

-

Simple interface for operator adjustments

According to the International Manufacturing Technology Council, PLC-controlled systems improve production consistency by up to 47% compared to manual operations.

Industry Applications

Down pipe bending and shaping machines serve multiple critical industries:

-

Construction: Drainage and downspout systems for commercial/residential buildings

-

HVAC: Ductwork and ventilation piping

-

Infrastructure: Culverts and drainage systems

-

Automotive: Exhaust and structural components

-

Agriculture: Irrigation and drainage systems

The versatility of these machines makes them indispensable for modern manufacturing. The Fabricators & Manufacturers Association notes that cold roll forming has become the preferred method for pipe production due to its efficiency and material conservation benefits.

Material Compatibility and Versatility

While optimized for 0.5-0.6mm color steel, our pipe shaping and bending equipment handles various materials:

-

Galvanized steel (standard and pre-painted)

-

Aluminum alloys

-

Stainless steel (specific grades)

-

Copper and copper alloys

-

Composite metal materials

The 45# steel rollers ensure durability even with harder materials, while the adjustable stations accommodate different thicknesses and diameters.

Why Choose Our Cold Roll Forming Machine?

-

Precision Engineering: 19-station design ensures perfect gradual forming

-

Speed Flexibility: Variable speeds for different production requirements

-

Energy Efficiency: Optimized power consumption reduces operating costs

-

Low Maintenance: Durable components minimize downtime

-

Safety Features: Comprehensive protection systems for operators

-

Customization Options: Adjustable for various pipe diameters and profiles

Comparative Advantages Over Traditional Methods

Compared to manual bending or hydraulic pressing, our down pipe shaping and bending system offers:

-

300% faster production rates

-

60% less material waste

-

Consistent quality across all products

-

Lower labor requirements

-

Safer working conditions

Installation and Support

Our comprehensive service package includes:

-

Factory testing before shipment

-

Installation supervision by certified engineers

-

Operator training programs

-

Ongoing technical support

-

Spare parts availability

-

Regular maintenance schedules

Future Developments in Pipe Forming Technology

The cold roll forming machine industry continues evolving with:

-

IoT integration for remote monitoring

-

AI-assisted quality control systems

-

Energy recovery systems

-

Quick-change roller technology

-

Enhanced safety interfaces

Conclusion

Investing in a high-quality down pipe shaping and bending cold roll forming machine transforms manufacturing capabilities, offering precision, efficiency, and reliability unmatched by traditional methods. Our 19-station system with PLC control represents the current standard in pipe production technology, delivering consistent results while minimizing operational costs. For manufacturers seeking to enhance their pipe production capabilities, this equipment provides the perfect balance of performance and value.

Contact Information

Ready to upgrade your manufacturing process? Contact our engineering team today to discuss how our down pipe shaping and bending cold roll forming machine can optimize your production line and improve your bottom line.