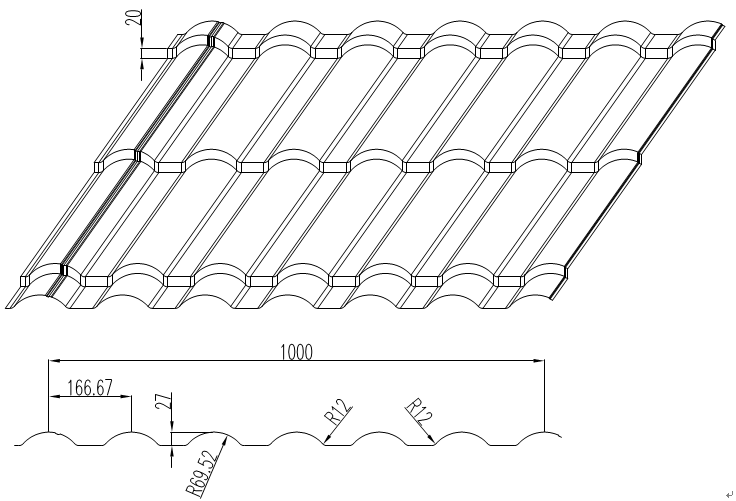

Glazed Roof Forming Machine

–Technique Proposal YX27-166.7-1000

A. Drawing of the plate

B.The main technical parameters

- Raw material of the panel: color steel( prepainted steel), thickness is 0.4-0.6mm, width is about 1200mm, effective width is 1000mm.

- The height of stanza is 20+1mm.

- Rolling speed: 0-3m/min

- Roll station: 16 steps.

- Roller’s material: 45# high quality steel finishing processing, the surface of hard chromium plating

- Main shaft material: 45# high-quality round steel , diameter: φ80mm

- Chainwheel material: 45# , 18 teeth, 16A

- Stander: welding by 350*175H steel welding, 16mm wall panel type, 6210 fine quality bearing.

- Main motor power: 5.5KW, cycloid pinwheel reducer., frequency control.

- The machine size(L*W*H): about 9500mm*1600mm*1600mm

- Complete computer control the length of stanza and panel, hydraulic forming cutter.

- Cutter material: Cr12Mov、quenching treatment.

- Motor power of hydraulic station: 4KW

- Electronic components: Schneider from France, PlC and transducer with mitsubishi from Japan.

- The main structure of the machine

The machine is constituted of passive-type hydraulic decoiler, guiding and feeding parts、forming parts、ladder profiling、cutting parts、hydraulic system、PLC computer controlling system、exit rack .

- Production process equipment

Decoiling→ guiding and feeding(through the school-oriented platform into the first roller) →roll forming→(roll forming through 16 rollers) →hydraulic ladder molding→hydraulic forming cutting→run out table(using exit rack)

E. Delivery time: After 75 working days from received the prepayment