L Bar Cold Roll Forming Machine: Precision Automation for Structural Steel Production

The L bar cold roll forming machine represents the pinnacle of automated metal forming technology for structural components. This complete production line integrates high-speed punching, servo feeding, and precision roll forming to create perfect L-bar profiles (30x30mm, 35x35mm, 40x40mm) used in construction, shelving, furniture, and industrial applications. By combining punching and forming in one automated sequence, this system eliminates multiple handling steps while achieving remarkable dimensional accuracy and production speeds up to 80 strokes per minute.

Why Choose This Automated L Bar Forming System?

Modern manufacturing demands efficiency and precision—exactly what this L bar cold roll forming machine delivers. Unlike traditional methods requiring separate punching and bending operations, this integrated line processes coil stock into finished L-bars in one continuous flow. The system’s PLC-controlled automation ensures consistent quality while reducing labor costs and material waste. According to the Fabricators & Manufacturers Association, integrated forming systems can improve production efficiency by 40-60% compared to manual operations.

Technical Specifications: Engineered for Performance

1. Straightening & Guide System

-

Straightening Rollers: 7 stations (3 up, 4 down)

-

Roller Material: 45# polished chrome-plated steel

-

Roller Diameter: 76mm

-

Guide System: Precision material alignment

-

Power: 5.5KW motor

2. High-Precision Servo Feeding

-

Servo Motor: 2.2KW

-

Feeding Speed: Maximum 60m/min

-

Feeding Length Range: 0.1-10,000mm

-

Feeding Accuracy: ±0.1mm

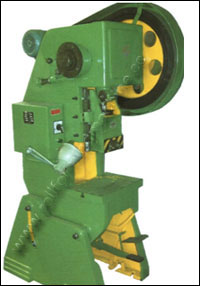

3. High-Speed Punching System

-

Punching Speed: 80 strokes/minute

-

Capacity: 80-ton Yangli punching machine

-

Hole Configuration: 32 holes per stroke (3-hole unit pattern)

-

Control: CNC-controlled punching distance

-

Mold Compatibility: Custom Cr12 molds for each profile size

4. Roll Forming Main Machine

-

Coil Width: Profile-dependent

-

Forming Speed: 0-15m/min

-

Roll Stations: 9 forming + 3 straightening stations

-

Roller Material: Gcr15 forged steel, chrome-plated (HRC58-62)

-

Shaft Material: 45# forged steel (ø65mm diameter)

-

Main Power: 7.5KW motor

-

Material Compatibility: 0.8-1.2mm galvanized steel (235MPa)

-

Transmission: 1.2-inch chain drive

5. Hydraulic Cutting System

-

Cutting Method: Post-forming hydraulic cut

-

Blade Material: Heat-treated CR12 steel

-

Length Measurement: Automatic encoder system

-

Length Tolerance: ±1.5mm for 3-meter sections

6. Control & Automation

-

PLC System: Panasonic industrial controller

-

Voltage: 380V/50Hz/3-phase (customizable)

-

Features: Automatic length/quantity control, error correction, production monitoring

Advanced Features That Set This Machine Apart

Multi-Size Flexibility

This L bar cold roll forming machine uniquely produces three standard sizes (30x30mm, 35x35mm, 40x40mm) with simple mold changes. The quick-change punching mold system minimizes downtime between production runs, making it ideal for manufacturers handling diverse orders.

Precision Engineering

Every component—from the chrome-plated straightening rollers to the heat-treated cutting blades—is engineered for durability and precision. The Gcr15 steel forming rollers maintain their tolerance through millions of cycles, ensuring consistent profile accuracy. As noted in ASM International’s materials handbook, chrome plating significantly extends roller life in continuous forming applications.

Smart Control Integration

The Panasonic PLC system transforms complex operations into simple automated processes. Operators can:

-

Set production quantities with automatic shutdown

-

Adjust lengths with ±1.5mm precision

-

Monitor real-time production data

-

Implement quick changeovers between profiles

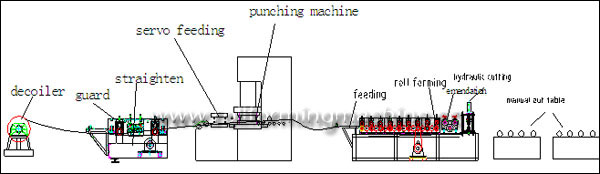

Production Workflow & Layout

The complete line follows an optimized linear layout:

-

Coil loading → 2. Straightening & guiding → 3. Servo feeding → 4. CNC punching → 5. Roll forming → 6. Straightening correction → 7. Hydraulic cutting → 8. Finished product output

This streamlined arrangement minimizes footprint while maximizing accessibility for maintenance and mold changes.

Applications & Industries Served

This L bar cold roll forming machine produces components for:

-

Building frameworks and structural supports

-

Warehouse storage systems and shelving

-

Furniture frames and industrial racks

-

Electrical enclosures and equipment mounts

-

Agricultural equipment and greenhouse structures

Comparative Advantages Over Traditional Methods

Speed & Efficiency

-

Traditional: 15-20 minutes setup per size change

-

This Machine: 5-7 minutes mold changeover

-

Production Rate: Up to 50% higher than manual lines

Precision & Consistency

-

Manual forming tolerance: ±3mm

-

Machine tolerance: ±1.5mm

-

Automated quality control eliminates human error

Cost Effectiveness

-

Reduced labor requirements (1-2 operators vs. 4-5)

-

Lower material waste (precision feeding reduces scrap)

-

Energy-efficient servo motors cut power consumption

Technical Support & Customization

We provide comprehensive support including:

-

Machine installation and operator training

-

Custom mold design for specialized profiles

-

Maintenance guidance and spare parts supply

-

Production optimization consulting

Request Your Customized Solution

Ready to upgrade your L-bar production? Contact our engineering team today for:

-

Detailed technical specifications

-

Customized machine configurations

-

Production capacity analysis

-

Pricing and delivery information

Contact us for more details.