7 Incredible Benefits of a Modern Leveling Cutting Machine for Flawless Production

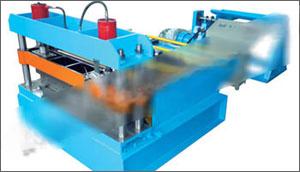

A Leveling Cutting Machine is the cornerstone of efficiency and precision in modern metal fabrication and processing lines. This integrated system, often called a cut-to-length (CTL) line, transforms coiled steel, aluminum, or other metals into perfectly flat, accurately dimensioned sheets or blanks. By combining a precision leveling unit with a synchronized feeding and cutting mechanism, it eliminates the inherent curvature and internal stresses of coil stock—a process critical for high-quality downstream manufacturing in industries from automotive to appliance production.

1. Unmatched Precision in Material Flattening

The heart of any leveling and cutting line is its leveling head. Our machines utilize advanced seven-roller leveling technology to ensure superior flatness. As the material passes through these progressively adjusted rollers, it undergoes alternating bending that neutralizes coil memory and residual stresses. This is essential for processing a wide material thickness range, from delicate 0.3mm strips to robust 16mm plates. Organizations like the Fabricators & Manufacturers Association highlight that consistent material flatness is fundamental to reducing waste and improving part quality in stamping and laser cutting.

2. Seamless Integration in a Cut-to-Length Line

A standalone leveler is powerful, but its potential is fully unlocked when synchronized within a complete coil processing system. Our Leveling Cutting Machine is typically composed of a decoiler, feeding unit, precision leveling head, measuring system, cutting device (shear or plasma), and stacking station. This integration allows for a continuous, automated workflow from coil to finished stack, dramatically increasing throughput and reducing manual handling. The main power of 5.5KW for the drive and a matching 5.5KW hydraulic station power ensure robust performance for demanding production schedules.

3. Versatility Across Materials and Dimensions

Flexibility is a key strength. These machines are engineered to handle a width between 500mm to 1950mm of varied rolling plates, making them suitable for a vast array of product sizes. Whether you’re producing large cabinet panels or smaller bracketry, the machine can be configured to match your needs. This ability to tidy and process varied materials maximizes your ROI and allows for quick changeovers between jobs.

4. Dramatic Reduction in Material Waste and Cost

Precision is profitability. Traditional methods of manually cutting from coiled material often lead to inaccuracies and flawed flatness, causing rejected parts. A precision sheet metal leveler within an automated line ensures each cut starts from perfectly flat stock, leading to optimal material utilization. The accurate measuring system minimizes off-cuts, directly translating to significant savings on raw material costs—one of the largest expenses in manufacturing.

5. Enhanced Production Speed and Throughput

Automation equals acceleration. By eliminating the separate, batch-oriented steps of leveling and then cutting, a coil leveling and cut-to-length machine creates a continuous flow. The synchronized operation, powered by efficient 5.5KW drives, means your line can produce more cut-to-length sheets per hour with consistent quality, allowing you to meet tighter deadlines and increase overall plant capacity.

6. Improved Worker Safety and Ergonomic Handling

Heavy coils and large sheets pose significant safety risks. An automated Leveling Cutting Machine confines the handling of heavy materials to a controlled mechanical process. The final output is neatly stacked blanked sheets, ready for safe and easy transport to the next workstation. This reduces the risk of strain injuries and accidents associated with manual material movement, creating a safer work environment.

7. Consistent, High-Quality Output for Downstream Operations

The ultimate goal is to provide perfect blanks for welding, painting, or assembly. Any warp or camber in a sheet can cause massive headaches in automated welding cells or precision assembly jigs. By guaranteeing a flawless, flat sheet, this machine ensures that every subsequent manufacturing step builds on a perfect foundation, reducing rework, improving fit-up, and elevating the quality of the final product. For in-depth technical standards on flatness, resources like the American Society of Mechanical Engineers provide valuable benchmarks.

Choosing the Right Leveling Cutting Machine

When selecting a heavy-duty leveling cutter, key specifications beyond material thickness range matter. Consider the required flatness tolerance, line speed, control system sophistication (e.g., CNC for preset lengths), and the type of cutting mechanism. Consulting with an experienced provider who understands your specific application—whether it’s for delicate electronics chassis or steel coil cutting for construction—is crucial to investing in a system that delivers these seven incredible benefits to your operation.

In conclusion, integrating a modern Leveling Cutting Machine into your production is not just an equipment purchase; it’s a strategic upgrade toward leaner, safer, and more profitable manufacturing. It transforms raw coiled metal into a reliable stream of precision feedstock, empowering your entire production chain.

Contact us now.