Revolutionary MCB Din Rail Channel Roll Forming Machine: Your Complete 2026 Guide

The MCB Din Rail Channel Roll Forming Machine represents the pinnacle of manufacturing efficiency for electrical component producers. This sophisticated equipment is specifically engineered to produce the standardized DIN rails that form the backbone of modern electrical distribution systems. From miniature circuit breakers (MCBs) to terminal blocks and other modular electrical devices, these rails provide the essential mounting structure that ensures safety, organization, and reliability in panels worldwide.

What is a DIN Rail and Why is Specialized Machinery Essential?

A DIN rail is a standardized metal rail used for mounting circuit breakers and industrial control equipment inside equipment racks. The consistency and precision of these rails are non-negotiable, as any deviation can lead to improper mounting, safety hazards, and system failures. This is where a dedicated MCB Din Rail Channel Roll Forming Machine becomes indispensable. Unlike general-purpose roll formers, this machine is optimized for the specific profile, tolerances, and material requirements of DIN rails, ensuring every piece meets international standards such as those outlined by the International Electrotechnical Commission (IEC). For more on DIN rail standards, you can refer to resources like IEC’s official publications.

Technical Specifications & Customizable Output

Our advanced MCB Din Rail forming machine is designed for versatility and precision, capable of producing rails to exact customer specifications. Below are two common configurations, but the machine can be tailored for numerous profiles.

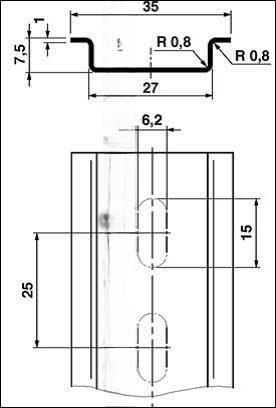

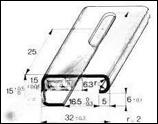

Configuration A: Standard 35mm Rail

-

Profile Height: 15mm

-

Length: 1000mm or 2000mm (customizable)

-

Profile Width: 35mm (the standard “top hat” rail width)

-

Base Material: Cold Rolled (CR) Steel Strips

-

Available Coatings: Galvanized (standard for corrosion resistance)

-

Material Thickness Range: 0.6mm, 0.8mm, 1.0mm, 1.2mm

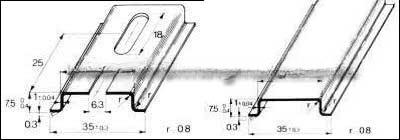

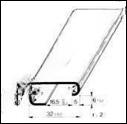

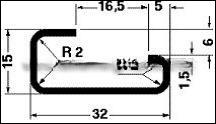

Configuration B: 32mm Rail Variant

-

Profile Height: 7.5mm

-

Length: 1000mm

-

Profile Width: 32mm

-

Base Material: Cold Rolled (CR) Steel Strips

-

Available Coating: Silver (often tin-plated for specific conductivity/solderability)

-

Material Thickness: 1.6mm

Key Advantages of Our Roll Forming Solution

Investing in a dedicated DIN rail channel roll forming machine offers transformative benefits for your production line:

-

Unmatched Precision & Consistency: Every rail produced has identical dimensions and mechanical properties, eliminating the variability common in manual or generic stamping processes.

-

High-Speed Production: Modern roll forming is a continuous process, allowing for the production of long lengths that can be cut to size, dramatically increasing output compared to piece-by-piece methods.

-

Material Efficiency & Strength: The cold roll forming process work-hardens the steel, increasing its strength without adding weight. It also generates minimal scrap compared to machining.

-

Remarkable Flexibility: Quick-change tooling allows the same MCB rail production machine to switch between different material thicknesses and, with adjustments, different profile sizes, making it ideal for job shops or manufacturers with diverse product lines.

-

Integrated Operations: Our machines can be equipped with auxiliary stations for punching, notching, embossing, and automatic cutting, creating a seamless, end-to-end production cell from coil stock to finished rail.

Core Components of the Machine System

A complete MCB Din Rail Channel Roll Forming Machine line typically includes:

-

Decoiler & Feeder: Holds and steadily feeds the master coil of CR steel.

-

Pre-Punching/Notching Unit: (Optional) Adds mounting holes or identification marks before forming.

-

The Roll Forming Mill: The heart of the machine, featuring a series of precisely machined roller dies that gradually shape the flat strip into the final DIN rail profile.

-

Cut-Off Press: A high-speed flying cut-off system that shears the continuously formed profile to the pre-set length without stopping the line.

-

Run-Out Table & Stacker: Automatically collects and bundles the finished rails.

Applications Across Industries

The rails produced by this channel roll forming machine are critical in:

-

Electrical Panel & Enclosure Manufacturing

-

Industrial Automation & Control Systems

-

Renewable Energy (Solar/Wind) Inverter Production

-

Telecommunications Infrastructure

-

Railway and Transportation Control Gear

Choosing the Right Machine Partner

Selecting a manufacturer for your MCB Din Rail Roll Forming Machine requires careful consideration of build quality, control systems, after-sales support, and the ability to provide custom tooling. A partner with deep experience in electrical component manufacturing will understand the critical tolerances required.

Conclusion: Elevate Your Production Capability

In a competitive market, the quality of your components defines the quality of your final product. Integrating a specialized MCB Din Rail Channel Roll Forming Machine into your factory is a strategic investment in precision, efficiency, and scalability. It ensures you have complete control over a fundamental component of your electrical assemblies.

Ready to transform your DIN rail production? Contact our engineering team today to discuss your specific requirements, request a machine quotation, or see a virtual demonstration of our MCB Din Rail forming equipment in action.