Metal deck roll forming machines are the powerhouse behind the production of the structural floor decking used in countless commercial, industrial, and residential buildings. These specialized machines transform flat coils of steel into precise, high-strength deck profiles through a continuous cold-forming process. Investing in the right metal deck roll forming machine is crucial for manufacturers looking to produce durable, reliable decking that forms a composite bond with concrete, creating robust flooring systems.

What Are Metal Deck Roll Forming Machines?

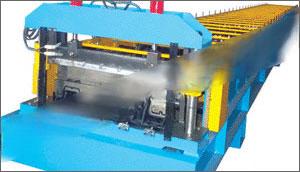

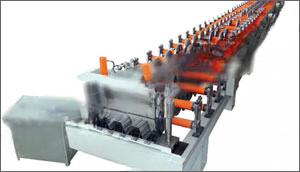

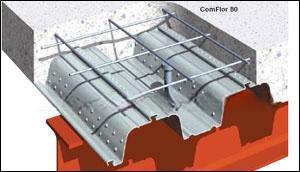

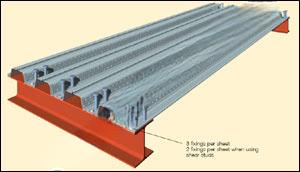

A metal deck roll forming machine is a type of roll former specifically engineered to produce metal floor deck profiles. The process involves feeding a continuous metal coil through a series of roller dies (stations), each progressively shaping the steel until it reaches the final cross-section. This method, as explained by resources like the Precision Metalforming Association, allows for high-volume production of consistent, high-tolerance parts with excellent material strength. The end product—metal decking—serves as a permanent formwork for concrete slabs, significantly increasing the floor’s load-bearing capacity and fastness.

Key Production Characteristics & Advantages

Modern metal deck roll forming machines are designed for performance and longevity. Here are their core benefits:

-

Enhanced Structural Integrity: Advanced machines utilize a reinforced station design, significantly increasing the overall strength and rigidity of the equipment. This allows for consistent forming under high tension, producing decking with superior dimensional accuracy.

-

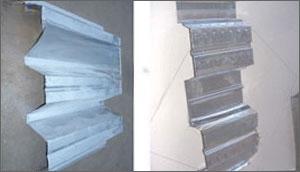

Purpose-Built for Floor Decking: The profiles produced are specifically engineered for construction flooring. The machine can emboss patterns or “dots” onto the sheet. This texturing is not cosmetic; it dramatically increases the frictional bond between the steel deck and the poured concrete, preventing slippage and creating a true composite structural element, as outlined in construction material studies.

-

High Efficiency & Automation: With integrated PLC control systems (like Panasonic) and hydraulic power units, these machines offer remarkable operational stability and speed, minimizing manual intervention and boosting output.

-

Material Versatility: While specifications vary, a typical metal deck roll forming machine can handle a range of material thicknesses (e.g., 0.8mm to 1.5mm), allowing production of different deck grades for various load requirements.

-

Durability and Low Maintenance: Built with heavy-duty components and chain-driven stability, these machines are designed for continuous operation in demanding industrial environments, ensuring a long service life.

Detailed Technical Specifications

Understanding the specs is key to selecting the right equipment. Here’s a breakdown of common parameters for a metal deck roll forming machine:

-

Material Width: Up to 1250 mm (coil width).

-

Material Thickness Range: Typically 0.8 – 1.5 mm, suitable for most structural decking applications.

-

Forming Speed: 12-15 meters per minute, balancing speed with precision.

-

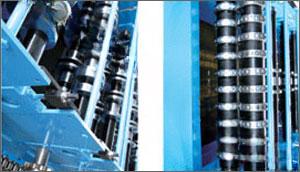

Number of Roll Stations: Often between 28 to 32 stations (can range higher for complex profiles). Each station performs a incremental part of the form.

-

Power Configuration:

-

Main Power: 22-30 KW (frequently using dual 11KW motors for the forming rolls).

-

Hydraulic Station Power: ~5.5 KW for the cutting system.

-

-

Control System: Industry-standard PLC (Programmable Logic Controller), such as Panasonic, for automated, repeatable operation.

-

Drive System: Robust chain drive mechanism ensuring synchronized movement of all roller stations.

Applications of the Finished Product

The decking produced by these machines is essential in modern construction. It is used to create composite floors in high-rise buildings, shopping malls, warehouses, and parking garages. Its ability to act as both a working platform during construction and permanent tensile reinforcement afterward makes it indispensable. For more on composite deck design principles, refer to engineering resources like The American Institute of Steel Construction.

How to Choose the Right Machine

Selecting a metal deck roll forming machine requires careful consideration:

-

Profile Complexity: Ensure the machine has enough roll stations to accurately form your desired deck profile.

-

Production Volume: Match the machine’s speed (m/min) to your output goals.

-

Material Specifications: Verify the machine can process your required steel grade and thickness.

-

Automation Level: Consider the need for automatic feeding, cutting, and stacking systems to create a complete production line.

-

Supplier Reputation: Choose a manufacturer with proven expertise in building durable, precision roll forming equipment.

In conclusion, a modern metal deck roll forming machine is a significant but worthwhile investment for any manufacturer serving the construction sector. By understanding their characteristics, specifications, and benefits, you can make an informed decision that enhances your production capability, product quality, and ultimately, your competitiveness in the market. Contact us now.