Innovative No Girder Curve Roll Forming Machine: Revolutionizing Large-Span Arch Roof Construction

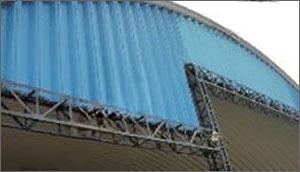

A No Girder Curve Roll Forming Machine is a highly specialized piece of industrial equipment engineered to produce curved, self-supporting arch panels directly from metal coil. These panels create robust, clear-span structures without the need for internal support beams or girders, hence the name “No Girder.” This powerful technology is revolutionizing the construction of wide, open spaces, offering a seamless and cost-effective solution for roofing large areas.

How the No Girder Curve Roll Forming Machine Works

Unlike traditional straight roll formers, a curve roll forming machine without girders utilizes a series of precisely aligned roll stations (17 to 20 stations in common models) that progressively bend the metal strip into a smooth, continuous arch profile. The key distinction is its ability to impart a permanent curve along the length of the panel as it forms the cross-sectional profile. According to the Fabricators & Manufacturers Association, International (FMA), roll forming is valued for its high-volume precision and consistency, which is critical for structural components. This machine’s design ensures each panel is uniform, strong, and ready for rapid on-site assembly.

5 Key Advantages of This Machine Technology

Choosing a dedicated No Girder Curve Roll Former offers transformative benefits for builders and fabricators:

-

Unobstructed Interior Space: The primary advantage is the creation of vast, column-free interiors. The arched panels themselves form the load-bearing structure, maximizing usable space—perfect for vehicle movement in garages or storage in warehouses.

-

Superior Structural Integrity: The continuous arched shape is inherently strong, efficiently distributing loads and offering excellent resistance to environmental stresses like wind and snow. The girder-less curve forming process results in a monolithic structure.

-

Rapid Construction & Cost Savings: Panels are produced on-site or prefabricated quickly and interlock seamlessly, drastically reducing labor time and material costs associated with traditional steel framing and girders.

-

Material & Design Efficiency: The process minimizes material waste by forming directly from coil. The elegant arch design also allows for efficient water and snow runoff.

-

Long-Span Capability: This is its most powerful feature. A high-quality No Girder arch forming machine can produce panels for structures with spans reaching up to 30 meters (approx. 100 feet), a feat difficult and expensive to achieve with conventional methods.

Primary Applications: Where is This Machine Used?

The products from a No Girder Curve Roll Forming Machine are ideal for any application requiring wide, clear-span coverage. The most common uses include:

-

Commercial and Private Vehicle Garages: Creating large, open shelters for auto dealerships, fleet storage, or farm equipment.

-

Warehouses and Storage Buildings: Offering expansive, unobstructed floor space for pallet racking and logistics.

-

Agricultural Buildings: Such as machinery sheds, hay barns, and riding arenas.

-

Recreational Facilities: Covering indoor sports areas or swimming pools.

-

Industrial Workshops: Providing wide bays for assembly lines or large equipment.

Detailed Technical Specifications of Common Models

Understanding the capabilities of a No Girder Curve Roll Forming Machine requires a look at its core specifications. Here are detailed breakdowns for two typical configurations:

Model A: Standard Duty Machine

-

Material Width: 914 mm (36 inches)

-

Material Thickness Range: 0.8 – 1.5 mm

-

Line Working Speed: 12 – 15 meters per minute

-

Number of Roll Stations: 17 Stations

-

Main Drive Power: 7.5 KW

-

Hydraulic System Power: 5.5 KW

-

Control System: Panasonic PLC (for reliable automation and precision)

-

Drive Mechanism: Chain Drive for robust power transmission

Model B: Enhanced Capacity Machine

-

Material Width: 600 mm (24 inches)

-

Material Thickness Range: 0.8 – 1.5 mm

-

Line Working Speed: 12 – 15 m/min

-

Number of Roll Stations: 20 Stations

-

Main Drive Power: 11 KW

-

Hydraulic System Power: 4 KW

-

Control System: Panasonic PLC

-

Drive Mechanism: Chain Drive

These specs highlight the machine’s versatility in handling different panel widths and its reliance on a strong PLC-controlled roll forming system for consistent, high-quality output.

Critical Considerations Before Investing

Investing in a No Girder Curve Roll Forming Machine is a significant decision. Key factors to evaluate include:

-

Required Span and Load Capacity: Match the machine’s maximum output (like the 30m span) to your project requirements.

-

Material Compatibility: Ensure it can process the grade and coating (e.g., galvanized steel, aluminized steel) you plan to use.

-

Production Speed & Volume: The 12-15 m/min speed suits continuous projects. Assess if this meets your throughput needs.

-

Tooling and Changeover: Understand the complexity and time required to change profiles, if different arch shapes are needed.

-

Supplier Support: Choose a manufacturer that provides comprehensive training, maintenance support, and access to spare parts.

Why Partner with a Specialist Manufacturer?

A reliable manufacturer of a No Girder Curve Roll Forming Machine does more than sell equipment. They provide engineering expertise to ensure the machine is configured for your specific panel profile and structural requirements. They offer critical support for tooling design, machine setup, and operator training, which are essential for producing panels that meet strict architectural and building code standards, as referenced in resources like the Metal Construction Association guidelines.

Conclusion: Building the Future with Clear-Span Design

The No Girder Curve Roll Forming Machine represents a leap forward in metal construction technology. It solves the fundamental challenge of covering large areas efficiently, strongly, and economically. By eliminating interior supports, it opens up new possibilities for architectural design and functional space utilization. For any business involved in constructing garages, warehouses, or agricultural buildings, integrating this machine into your fabrication process can be a game-changing competitive advantage, enabling you to deliver superior structures faster and at a better value.

Ready to explore how a No Girder Curve Roll Forming Machine can transform your building projects? Contact us for detailed specifications, project case studies, and expert consultation to find the perfect model for your needs.