Cable tray roll forming machine technology is the backbone of modern electrical infrastructure manufacturing, enabling the high-speed, precise production of cable support systems. This fully automated production line is engineered to transform raw steel coil into finished cable trays and channel support brackets with exceptional consistency and minimal manual intervention. For factories aiming to dominate the market in cable management solutions, understanding the capabilities and benefits of this integrated system is paramount. This detailed overview will dissect the machine’s robust specifications, operational advantages, and the comprehensive support that turns it from a simple piece of equipment into a long-term strategic partner for your business growth.

What is a Cable Tray Roll Forming Machine?

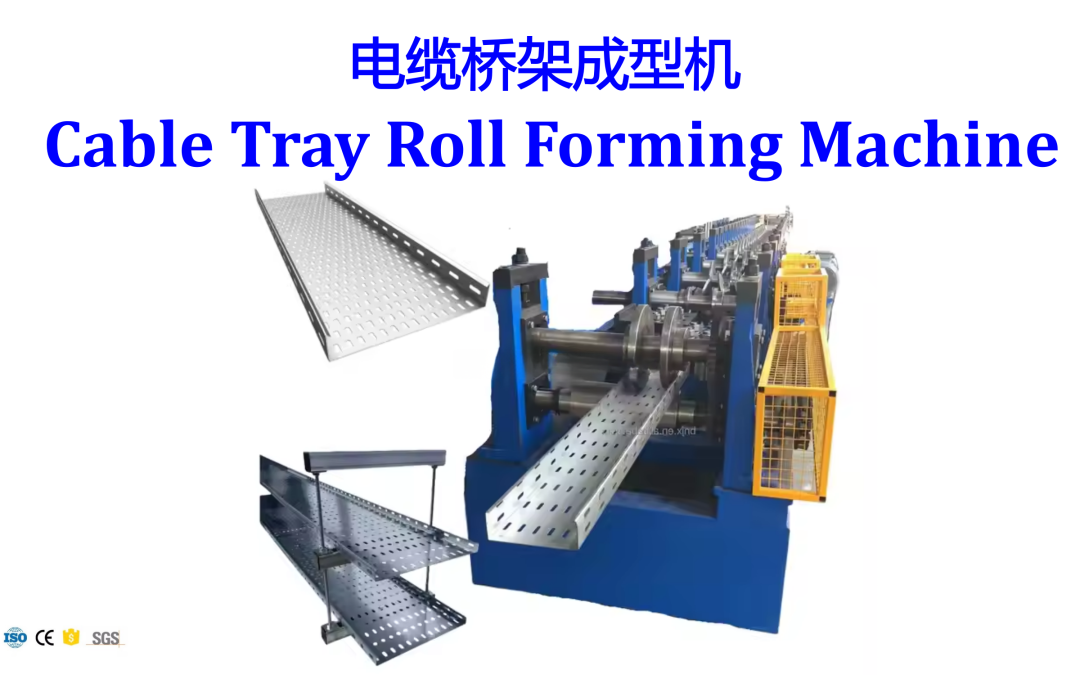

A cable tray roll forming machine is a highly specialized piece of industrial equipment designed for the continuous, cold-forming of metal coils into specific profiles. Unlike single-stroke presses, this machine passes the material through a series of precision-engineered roll stations, each progressively shaping the metal until the final cross-section—be it a ladder-type tray, a channel support bracket, or a custom profile—is achieved. This process, critical to modern manufacturing as noted by the Fabricators & Manufacturers Association, Intl. (FMA), is renowned for its high output and exceptional material consistency [Link to: https://www.fmamfg.org/].

Our system is not a standalone unit but a complete, integrated production line, from uncoiling the raw material to punching, forming, and cutting the final product to length.

Unmatched Technical Specifications for Peak Performance

The reliability of any industrial machinery is rooted in its technical DNA. Here, we break down the core components and specifications that make our cable tray roll forming machine a powerhouse of productivity and precision.

Power and Structural Integrity

-

Main Host Power: 15kw & Hydraulic Station Power: 5.5kw: This robust power configuration ensures the system can handle the high torque demands of forming steel up to 3.0mm thick without stalling or compromising on speed. The dedicated hydraulic system provides the immense force needed for punching and cutting operations.

-

Equipment Form: Archway Structure: The archway (or gantry) design provides a rigid, stable framework that minimizes vibration and deflection during high-speed operation. This structural integrity is crucial for maintaining the tight length tolerance of 3m ±1.5mm across all produced trays and brackets.

Precision Engineering and Control

-

Control Mode: Panasonic PLC: The Panasonic Programmable Logic Controller is the intelligent brain of the entire automated roll forming line. It synchronizes every component—from the decoiler to the cutter—ensuring seamless operation, repeatable accuracy, and easy troubleshooting.

-

Number of Molding Passes: 18 Lanes with Electric Width Adjustment: The 18-stage forming process allows for the creation of complex and rigid profiles with smooth, precise bends. The electric width adjustment feature is a significant advantage, enabling quick changeovers between different tray or bracket widths with minimal downtime, directly from the control console.

-

Roll and Shaft Material: The use of Gcr15 steel for rolls, hardened and chrome-plated, and 45# steel for the large Ø100mm shafts, ensures exceptional wear resistance and longevity, even under continuous production loads.

Material and Production Capabilities

-

Pressed Plate Thickness: 1.5-3.0mm: This range demonstrates the machine’s versatility, capable of producing lightweight trays as well as heavy-duty industrial support brackets and channels that meet rigorous load-bearing standards.

-

Scissors Material: Cr12Mov, quenched: The cutting blades are made from high-grade, hardened tool steel to maintain a sharp edge, ensuring clean, burr-free cuts throughout the machine’s lifecycle.

The Complete Production Line: From Coil to Finished Product

This cable tray roll forming machine is a complete ecosystem. The equipment composition includes:

-

Decoiler: Holds and feeds the master steel coil.

-

Hydraulic Punching Machine: Precisely punches holes for mounting or ventilation as required.

-

Main Roll Forming Machine: The heart of the line, where the profile is shaped.

-

PLC Control Console: The user-friendly interface for operators.

-

Hydraulic Station: Powers the punching and cutting mechanisms.

-

Wide Discharge Table: Safely collects the finished, cut-to-length trays or brackets.

Six Game-Changing Advantages for Your Business

Investing in this high-caliber cable tray roll forming machine translates into direct, measurable benefits that enhance your competitive edge.

-

Total Customization: We specialize in building machines to your exact profile specifications. “Different countries have different profiles,” and our engineering team will design and produce a custom profile machine tailored to your market’s needs.

-

Unbeatable Efficiency: With a fully automatic roll forming process, production speeds skyrocket while labor costs plummet. The line operates with minimal human intervention, maximizing output and consistency.

-

Superior Product Quality: The combination of the Panasonic PLC, high-precision rolls, and hardened cutting tools results in a finished product with consistent geometry, clean edges, and professional aesthetics that command market preference.

-

Reduced Operational Costs: The durability of components like Gcr15 rolls and Cr12Mov scissors minimizes maintenance downtime and replacement part costs, leading to a lower total cost of ownership.

-

Comprehensive Support Services: Our partnership extends beyond the sale. We provide engineering drawing design, raw material procurement assistance, shipping coordination, and on-site installation by our engineers.

-

Guaranteed Performance: With a 1-year warranty, a machinery test report before delivery, and remote video service support, we ensure your investment is protected and your production line starts strong.

Global Logistics and Partnership

We make international commerce seamless. The entire cable tray production line is expertly crated and loaded into a standard 20-foot or 40-foot container. Our technical team oversees the loading to prevent any transit damage. From the 80-day delivery timeline to the clear payment terms (30% deposit, 70% before shipment after your inspection), we operate with transparency and reliability.

Conclusion

In the competitive field of electrical infrastructure manufacturing, efficiency, flexibility, and quality are not optional. Our fully automatic cable tray roll forming machine is engineered to be the cornerstone of your production, enabling you to meet diverse customer demands with unparalleled speed and precision. It is more than machinery; it is a partnership aimed at fueling your growth and solidifying your reputation as a leader in cable support solutions.

Contact us for more details.