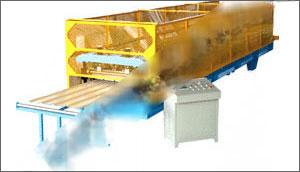

A roof wall panel roll forming machine is the backbone of modern construction material manufacturing, designed to produce both structural and cladding components with unparalleled efficiency. This versatile equipment transforms raw steel coils into precise, high-strength roofing and wall panels in a continuous, automated process. For fabricators serving the prefab housing, commercial construction, and industrial shed sectors, integrating this machine is a transformative step toward dominating the market.

This guide will explore the incredible capabilities of this machine, its technical specifications, and the direct benefits it brings to your bottom line.

How a Roof Wall Panel Roll Forming Machine Transforms Production

The operation of a roof wall panel roll forming machine is a masterpiece of precision engineering. It begins with a decoiler that holds and feeds a large coil of steel into the system. The metal strip then passes through a series of consecutive roll stations. Each station is equipped with a custom-designed set of rolls that incrementally bend the steel into the desired complex profile without any heat application. This “cold forming” process preserves the metal’s tensile strength and ensures a consistent, high-quality finish across every meter of panel produced.

This method is vastly superior to manual or press-brake forming for long, continuous profiles, as it eliminates inconsistencies and significantly reduces labor costs. For an in-depth look at metal forming technologies, the Fabricators & Manufacturers Association, Intl. (FMA) is an excellent external resource.

Why Our Roof Wall Panel Roll Forming Machine is a Game-Changer

Investing in our roof wall panel roll forming machine delivers a tangible return on investment through several key advantages:

-

Dual-Function Versatility: Why buy two separate machines? This single system expertly produces both roof panels and wall panels, maximizing your factory floor space and equipment budget. With quick roll changes, you can switch between profiles to meet diverse customer orders.

-

Blistering Production Speeds: With operational speeds reaching up to 30 meters per minute, this machine can produce kilometers of panels in a single shift. This high throughput allows you to take on larger projects and meet tight deadlines with confidence.

-

Uncompromising Quality and Consistency: Every panel that comes off the line is identical. The PLC-controlled process guarantees perfect dimensional accuracy, wave pattern, and interlocking edges every time, which is critical for water-tight roofing systems and seamless wall installations.

-

Superior Material Strength: The cold-forming process work-hardens the steel, enhancing its rigidity and durability. The resulting roof and wall panels can withstand harsh weather conditions and heavy loads, ensuring long-term structural integrity for your clients’ buildings.

Detailed Specifications of Our Roof Wall Panel Roll Forming Machines

We offer a range of models to suit different production volumes and material requirements. All models feature robust construction and a user-friendly Panasonic PLC control system for reliable operation.

Model RW-100: Standard Versatile Performer

-

Material Thickness: 0.4 – 0.8mm

-

Working Speed: 12 – 30 m/min

-

Roll Stations: 18 stations

-

Main Motor Power: 7.5 KW

-

Hydraulic Power: 3 KW

-

Drive System: Heavy-Duty Chain Drive

Model RW-200: Economical & Efficient

-

Material Thickness: 0.4 – 0.8mm

-

Working Speed: 12 – 30 m/min

-

Roll Stations: 18 stations

-

Main Motor Power: 5.5 KW

-

Hydraulic Power: 3 KW

-

Drive System: Chain Drive

Model RW-300: Heavy-Duty Powerhouse

-

Material Thickness: 2.0 – 4.0mm

-

Working Speed: 15 m/min

-

Roll Stations: 18 stations

-

Main Motor Power: 37 KW

-

Hydraulic Power: 7.5 KW

-

Drive System: High-Torque Gear Drive

Applications: Where is This Machine Used?

The application for this roof and wall panel line is extensive across the global construction industry. It is the ideal solution for producing panels for:

-

Prefabricated Steel Structures: Rapidly produce all cladding for warehouses, factories, and aircraft hangars.

-

Commercial and Residential Roofing: Manufacture durable, leak-resistant roofing sheets for shopping malls, apartment complexes, and single-family homes.

-

Industrial Sheds and Warehouses: Create the entire building envelope—both walls and roofs—with a single, efficient machine.

-

Agricultural Buildings: Produce panels for barns, silos, and storage facilities that require robust and cost-effective materials.

Understanding the building science behind these applications is crucial. For more information, the Whole Building Design Guide (WBDG) provides comprehensive resources on building envelope systems.

Choosing the Right Roof Wall Panel Roll Forming Machine for Your Needs

Selecting the correct model depends on your primary business focus. If you work with standard gauge steel for typical buildings, the RW-100 or RW-200 is perfect. However, if your projects involve thicker, structural panels for heavy-industry applications, the robust RW-300 with its gear drive is the necessary choice. Consider your target market, the most common material thickness you use, and your desired output speed.

Conclusion: Build Your Future with Automated Production

A roof wall panel roll forming machine is not just a piece of equipment; it’s a strategic asset that automates your most critical production process. It slashes operational costs, minimizes human error, and ensures you deliver a superior product that builds your company’s reputation. By enabling you to produce both roof and wall panels, it offers unparalleled flexibility to capture a larger share of the construction market.

We provide a comprehensive range of custom roll forming solutions. Contact us today to discuss your specific requirements and let us help you select the perfect roof wall panel roll forming machine to skyrocket your profits.