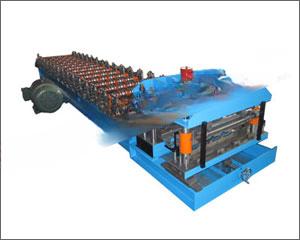

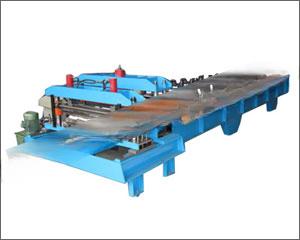

Revolutionary Single Pressed Mold Steel Tile Forming Machine: 16-Station Precision & High-Speed Output

A single pressed mold steel tile forming machine represents the pinnacle of efficiency and precision in modern metal roofing manufacturing. This specialized roll forming equipment transforms coiled steel into consistent, high-strength roofing tiles through a continuous, automated process. Designed for durability and aesthetic flexibility, it is the core of productive roofing material production lines worldwide.

Unmatched Production Characteristics and Applications

The primary advantage of this single pressed mold technology lies in its integrated, streamlined approach. Unlike multi-stage systems, it consolidates forming, punching, and cutting into one synchronized operation. This machine adopts reinforced stations to ensure exceptional solidity and vibration-free performance, directly translating to product consistency.

The steel tiles produced are not merely functional; they elevate architectural aesthetics. These products are widely specified for:

-

Modern commercial and residential roofing systems

-

Industrial building cladding

-

Renovation projects requiring durable, stylish materials

-

Architectural designs demanding specific profiles and colors

By enhancing housing and building aesthetics with consistent, weather-resistant tiles, this machine creates tangible value for manufacturers and end-users alike.

In-Depth Technical Specifications: Two Powerhouse Models

Our steel tile forming machine is engineered for versatility and is available in optimized configurations to match different production volume needs.

Model A: High-Speed Production Workhorse

-

Material Thickness: 0.3 – 0.8 mm

-

Forming Speed: 5 – 6 meters per minute

-

Roll Stations: 16 stations (configurable based on final profile design)

-

Main Drive Power: 4.4 KW Servo Motor (for precision speed control)

-

Hydraulic System Power: 4 KW

-

Control System: Panasonic PLC (Programmable Logic Controller)

-

Drive Mechanism: Chain drive for robust power transmission

Model B: High-Torque Precision Former

-

Material Thickness: 0.3 – 0.8 mm

-

Forming Speed: 2 – 4 meters per minute

-

Roll Stations: 16 stations (configurable based on final profile design)

-

Main Drive Power: 5.5 KW

-

Hydraulic System Power: 4 KW

-

Control System: Panasonic PLC

-

Drive Mechanism: Chain drive

Both models demonstrate the core principle of the single pressed mold system: precise, station-by-stage deformation of metal coil into a finished tile profile with minimal handling.

Why the 16-Station, Single-Press Design is a Game-Changer

The 16-station architecture is crucial. Each station performs a incremental forming step, ensuring the steel is shaped gradually and accurately without stressing the material. This prevents imperfections and maintains the metallurgical integrity of the tile. The single pressed mold process, governed by the PLC, guarantees every tile is identical, which is critical for seamless roof installation and waterproofing performance.

The integration of a servo motor in Model A allows for exceptional control over the forming speed and position, reducing material waste and energy consumption. Industry resources like the Fabricators & Manufacturers Association, Intl. (FMA) highlight the importance of such precision automation in improving manufacturing competitiveness.

The Heart of the System: PLC Control & Robust Drive

The Panasonic PLC is the brain of the operation. It unifies control over:

-

The roll forming speed and synchronization

-

The hydraulic cutting and punching system

-

Fault diagnostics and safety interlocks

This automation allows for quick changeovers between different tile profiles by adjusting the PLC program and tooling, making the machine highly adaptable.

The chain drive system provides a reliable, maintenance-friendly method of transferring power to all forming stations, ensuring they rotate in perfect unison—a non-negotiable requirement for a quality steel tile forming machine.

Maximizing Your ROI with Advanced Tile Production

Investing in this single pressed mold steel tile forming machine is an investment in production capacity and product quality. Key benefits include:

-

Reduced Labor Costs: Automated, continuous operation minimizes manual intervention.

-

Minimal Material Waste: Precise control and cutting optimize coil usage.

-

High Output Consistency: Produces uniform tiles that simplify installation and enhance customer satisfaction.

-

Profile Flexibility: Ability to produce various tile styles to meet market trends.

Partner with a Specialist for Your Forming Solutions

Selecting the right equipment is critical. We provide not just machines, but comprehensive support—from profile design consulting to installation guidance—ensuring your single pressed mold system delivers maximum productivity from day one.

Request Detailed Specifications Today

Transform your roofing manufacturing capabilities. Contact us for full technical datasheets, video demonstrations of our single pressed mold steel tile forming machine in action, and personalized consultation to identify the perfect model (A or B) for your production goals.

Related roll forming machine: