Maximize Output: The Ultimate T Bar Ceiling Roll Forming Machine for Precision Manufacturing

The T Bar Ceiling Roll Forming Machine is the cornerstone of modern, efficient ceiling grid production. This high-precision, PLC-controlled system transforms metal coils into flawless T Bar profiles with unmatched speed and accuracy, making it an indispensable asset for manufacturers worldwide.

Unmatched Technical Specifications for Superior Performance

Our T Bar Ceiling Roll Forming Machine is engineered for durability and high-volume output. Here are the core specifications that set our machine apart:

-

Production Speed: Operates at 12-15 meters per minute, ensuring high throughput.

-

Roller Configuration: Features 9 rollers, including 3 for precise profile adjustment.

-

Drive System: Utilizes a robust single-chain transmission for reliable, consistent motion.

-

Material Compatibility: Processes Q195 and Q235 steel with a standard thickness of 0.5mm (capable of 0.5mm to 1.0mm).

-

Critical Components: Shafts are made from quenched 45# steel (HRC 58-62) and chrome-plated for longevity. Cutting blades are crafted from durable Cr12Mov steel.

How the T Bar Ceiling Roll Forming Machine Transforms Production

This automated system streamlines the entire fabrication process:

-

Load: The decoiler feeds the metal coil into the machine.

-

Feed & Guide: The material is precisely guided into the forming station.

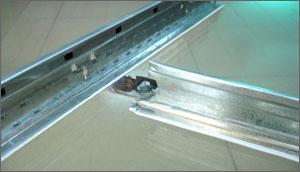

-

Roll Forming: The heart of the operation, where the T Bar ceiling roll forming machine uses its series of rollers to progressively shape the flat metal into the precise T Bar cross-section.

-

Cutting & Discharge: A hydraulic, PLC-triggered cutter ensures accurate cut lengths (tolerance: ±1.5mm for 3m bars) before the finished product is discharged.

Key Advantages of Investing in Our Roll Forming Technology

Choosing our T Bar Ceiling Roll Forming Machine offers tangible benefits for your business:

-

Exceptional Precision: Achieve consistent profile accuracy and tight length tolerances, reducing material waste and rework.

-

High-Speed Operation: Meet large order deadlines with a production speed of up to 15m/min.

-

Robust Construction: Built with hardened steel shafts and quality components for minimal downtime and a long service life, as emphasized in industry guides on machine maintenance.

-

Ease of Operation: The user-friendly PLC control system (featuring brands like Panasonic) simplifies setup, operation, and changeovers.

Applications & Customization: Beyond Standard T Bars

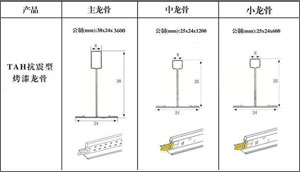

While designed for standard ceiling grid profiles, our T Bar ceiling roll forming machine is highly adaptable. We can customize the roller sets and tooling to produce various secondary ceiling grid components or other lightweight structural profiles, aligning with specifications like Chinese Standard GB/6723-86 or your custom drawings.

Why Partner With Us for Your Forming Equipment?

As a specialist in roll forming technology, we provide more than just a machine. We offer comprehensive support, from installation and training to ongoing technical service and spare parts. Our expertise ensures you integrate the T Bar Ceiling Roll Forming Machine seamlessly into your production line for maximum ROI.

Conclusion: Elevate Your Manufacturing Capability

For manufacturers seeking reliability, speed, and precision in ceiling grid production, the T Bar Ceiling Roll Forming Machine is the definitive solution. It represents a smart investment that boosts productivity, enhances product quality, and strengthens your competitive edge in the construction materials market.

Contact us now.