The Ultimate 5-Step Guide to Our Powerful Track Cold Roll Forming Machine

A track cold roll forming machine is the cornerstone of modern, efficient metal profile production. This sophisticated piece of equipment transforms flat sheets of steel into consistent, high-strength tracks and C-purlins, which are essential components in construction, storage systems, and industrial frameworks. If you’re looking to boost your production line’s output and precision, understanding the capabilities of a dedicated roll forming system is the first critical step. This guide will walk you through the five key aspects of our powerful and reliable machine.

What Exactly is a Track Cold Roll Forming Machine?

At its core, a track cold roll forming machine is a continuous bending operation where a coil of sheet metal is passed through a series of mated rolls (stations), each performing an incremental part of the bend until the desired cross-sectional profile is achieved. The “cold” process means the metal is formed at room temperature, which increases its strength through work-hardening. Unlike press braking, this method creates a uniform product with no stress marks at high speeds, making it perfect for long, high-volume runs of structural components like load-bearing tracks and C-purlins.

For a deeper understanding of the cold roll forming process, the Fabrisonic explanation of roll forming provides an excellent technical overview.

Unbeatable Advantages of Our Roll Forming System

Why should you choose this specific track roll forming solution? The benefits are substantial:

-

Exceptional Speed & Efficiency: With a forming speed of 10-15 meters per minute, our machine dramatically outperforms traditional fabrication methods.

-

Superior Consistency & Quality: Every profile produced is identical, eliminating human error and ensuring perfect fit and function in your final assemblies.

-

Remarkable Material Strength: The cold-forming process work-hardens the steel, resulting in a final product that is stronger than the original raw material.

-

Reduced Operational Costs: High automation and minimal manual intervention lead to lower labor costs and less material waste over time.

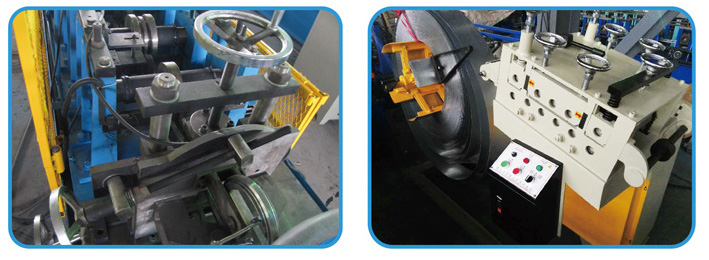

Core Specifications of Our High-Performance Machine

Our machine is engineered for power and durability. Here are the key technical specifications that set it apart:

-

Material Thickness: Handles a robust range from 1.5mm to 3mm, making it suitable for both light and heavy-duty applications.

-

Forming Speed: Operates at an efficient 10-15 meters per minute, optimizing your production throughput.

-

Roll Stations: Configured with 18 stations (can be customized based on profile complexity) to ensure a smooth and precise forming process.

-

Drive System: A reliable chain drive mechanism provides the torque and stability needed for continuous operation.

Power and Control: The Brains and Brawn

The performance of any steel forming machine hinges on its power and control systems. Ours is built to deliver unwavering reliability.

-

Main Power: A strong 30kW motor provides the primary driving force for the entire system.

-

Hydraulic Power: A dedicated 7.5kW hydraulic unit powers the cutting mechanism for clean, burr-free cuts.

-

Control System: At the heart of the operation is a Panasonic PLC. This advanced controller ensures precise synchronization of all functions, from uncoiling to cutting, and allows for easy setup and operation.

-

Cutting Tooling: The shear is made from CR12 tool steel, a high-carbon, high-chromium alloy known for its exceptional wear resistance and long service life, ensuring clean cuts over millions of cycles.

Key Industries That Rely on Track Forming Equipment

The versatility of the profiles produced by our C purlin making machine makes it indispensable across several sectors:

-

Construction: For creating structural C-purlins, roof battens, and wall girts.

-

Storage Systems: Manufacturing upright frames and beam tracks for pallet racking and shelving units.

-

Industrial Framing: Producing custom tracks for partition walls, mezzanine floors, and conveyor systems.

To see how these components are used in large-scale projects, you can explore resources from the American Institute of Steel Construction.

Conclusion: Invest in Precision and Power

Investing in a high-quality track cold roll forming machine is a strategic decision that pays dividends in productivity, product quality, and operational cost savings. Our machine, with its robust construction, precise PLC control, and powerful drive system, is designed to be a reliable workhorse for your business. By automating the production of critical steel profiles, you can scale your operations, meet demanding deadlines, and maintain a competitive edge in your market.

Contact us now and send inquiry.