Unlock Efficient Production with a Custom Two Layers Panels Making Machine

As a premier agent and engineer for cold roll forming machines in China, we specialize in turning unique client concepts into reality. We focus on delivering exceptional value by designing and sketching tailored solutions for your specific needs. Consequently, we often recommend a two layers panels making machine as the most powerful and efficient choice for manufacturers needing high output of complex profiles. This advanced system is a cornerstone for modern construction material production.

What is a Two Layers Panels Making Machine?

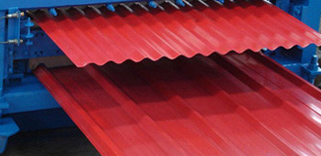

Simply put, a two layers panels making machine is a sophisticated piece of cold roll forming equipment. It is specifically engineered to produce dual-layer or double-layer panels in one continuous, automated process. Unlike standard single-panel machines, this system forms two separate metal sheets simultaneously, often creating a reinforced structural panel or the outer skins for insulated sandwich panels.

Therefore, if you produce roofing sheets, wall cladding, or composite sandwich panels, this machine is likely your ideal solution. According to industry resources like The Fabricator on Roll Forming, this technology is key for creating strong, consistent profiles for construction.

Why Choose a Double Layer Roll Forming Machine?

Choosing this machine offers major advantages. First, it significantly boosts productivity by forming two layers at once. Second, it ensures perfect alignment and consistency between the top and bottom layers, which is critical for product strength and appearance. Third, it streamlines your factory floor by combining two processes into one integrated line.

For example, imagine you need to make trapezoidal roof panels with a flat bottom layer. A dual layer panel machine can form both the trapezoidal top and the flat bottom sheet in sync, ready for assembly or direct use. This capability makes it a highly valuable investment for scaling your business.

How Does This Double Layer Machine Work?

The process is precise and efficient. While more advanced, it follows a logical sequence similar to single-layer forming:

-

Decoiling & Feeding: Two separate coils of metal are loaded and fed into the machine line.

-

Leveling & Guiding: Each sheet is straightened and guided to ensure perfect entry into the forming section.

-

Pre-Punching (Optional): If needed, holes or features can be added before forming.

-

Synchronized Roll Forming: This is the core stage. Both sheets pass through a series of rolling stations (or a dual-head system) where they are gradually shaped into the desired two layers panels profile.

-

Cutting: A flying cut-off system cuts the continuously formed double-layer product to precise lengths without stopping the line.

-

Output & Stacking: The finished panels are automatically conveyed and stacked for easy handling.

We design every stage, from feed to cut-off, to ensure smooth, high-speed operation for your specific panel profiles.

Key Applications and Industries

This versatile production machine is vital for several sectors:

-

Building & Construction: For making durable roofing panels, wall cladding, and decking.

-

Cold Storage & Clean Rooms: To produce the metal skins for PUF/EPS sandwich panels.

-

Partition & Door Manufacturing: For creating strong, lightweight composite panels.

-

Custom Architectural Profiles: For unique dual-layer facades and signage.

Essentially, any project that requires strong, lightweight, and visually consistent double-layer metal panels can benefit from this technology.

Our Unique Service: Design, Value, and Partnership

Our approach sets us apart. We start by listening to your custom requirements. Then, our engineers create detailed designs and sketches to match your exact product specs. After that, we don’t just sell you a machine; we recommend the most valuable solution for your budget and output goals. Often, this leads to a custom two layers panels making machine.

We pride ourselves on being more than a supplier; we are your technical partner in China. We ensure you get a robust, reliable, and efficient double layer roll forming machine that becomes a profit center for your factory.

Getting Started with Your Machine

Ready to upgrade your production? Contact us now to discuss your project. Share your panel profiles, material type, and desired output. We will then provide a custom design sketch and a transparent proposal for your high-performance two layers panels making machine. Let’s build your future, one panel at a time.