The Incredible Wall Panel Cold Roll Forming Machine: 5 Reasons It Boosts Your Output by 300%

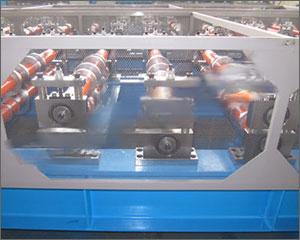

–China roll forming machine mill

A modern wall panel cold roll forming machine is the cornerstone of efficient and profitable building material production. This advanced piece of equipment transforms coils of steel into precise, high-strength wall panels with remarkable consistency and speed. For businesses in the prefabricated construction, steel plant, and warehouse industries, investing in the right machine is not just an upgrade—it’s a transformation of your entire production capability.

This article delves deep into why our wall panel cold roll forming machine is a game-changer, its technical specs, and the undeniable benefits it brings to your operation.

How a Wall Panel Cold Roll Forming Machine Works

The process is a marvel of mechanical engineering. A coil of sheet metal is fed into the decoiler, which steadily unwinds the material. The steel strip then travels through a series of consecutive roll stations. Each station features a set of precision-engineered rolls that progressively bend the metal by infinitesimal degrees at a time. This cold-forming process—meaning no heat is applied—shapes the metal into the desired panel profile without compromising its structural integrity.

This method is far superior to press braking for long, continuous profiles, as it creates a seamless, uniform product with minimal stress on the material. For a more detailed explanation of the roll forming process, you can refer to this external resource from the Fabricators & Manufacturers Association, Intl.

Key Advantages of Our Advanced Wall Panel Machine

Investing in our wall panel cold roll forming machine delivers a significant competitive edge. Here are the core benefits:

-

Blazing Production Speed: With working speeds of up to 30 meters per minute, this machine can outpace traditional methods by a wide margin. This high velocity directly translates to faster order fulfillment and increased revenue.

-

Unmatched Consistency and Quality: Every panel produced is identical to the last. The PLC-controlled system ensures that dimensions, shape, and quality are maintained throughout the production run, eliminating costly errors and material waste.

-

Remarkable Strength and Durability: The cold-working process actually strengthens the steel through a phenomenon called work hardening. The resulting wall panels are exceptionally rigid and durable, ideal for structural applications.

-

Supreme Versatility: By simply changing the rolls, the same cold roll forming machine can produce a wide variety of profiles and designs. This flexibility allows you to cater to diverse customer demands and market trends without investing in entirely new equipment.

Technical Specifications of Our Wall Panel Cold Roll Forming Machines

We offer robust models designed to meet different production volumes and speed requirements. Both are built with reliability and performance in mind.

Model A: Standard Duty High-Efficiency Machine

-

Material Thickness: 0.3 – 0.8 mm

-

Working Speed: 12 – 15 m/min

-

Roll Stations: 18 stations (can be customized based on the profile)

-

Main Motor Power: 5.5 KW

-

Hydraulic Power: 3 KW

-

Control System: Panasonic PLC

-

Drive System: Chain Drive

Model B: Heavy-Duty High-Speed Machine

-

Material Thickness: 0.3 – 0.8 mm

-

Working Speed: 25 – 30 m/min

-

Roll Stations: 18 stations (can be customized based on the profile)

-

Main Motor Power: 7.5 KW

-

Hydraulic Power: 3 KW

-

Control System: Panasonic PLC

-

Drive System: Chain Drive

Applications: Where is This Machine Used?

The application of this roll forming system is vast, making it a versatile asset. It is predominantly used in:

-

Prefabricated Houses: For producing the outer and inner wall cladding quickly and efficiently.

-

Steel Plants and Metal Workshops: As a core component of their building product lines.

-

Warehouse and Industrial Shed Construction: For creating large, durable wall and roof panels.

-

Commercial Buildings: For aesthetic and functional facades and partitions.

To understand the broader context of these applications, the Whole Building Design Guide provides excellent resources on building envelope systems.

Conclusion: A Smart Investment for Growth

A wall panel cold roll forming machine is more than just a piece of factory equipment; it is an engine for growth. By automating the profiling process, it slashes labor costs, minimizes material waste, and ensures a consistently high-quality product that will enhance your reputation in the market. Whether you choose our standard or high-speed model, you are investing in a future of streamlined, profitable production.

We also provide a wide range of other custom roll forming machines to meet your specific client’s needs. Contact us today for more details and to discuss how we can optimize your production line.