Transform Your Production with a High-Performance Welding Pipe Making Machine Line

A modern Welding Pipe Making Machine Line is the backbone of efficient tube and pipe manufacturing. This integrated system transforms raw steel coil into high-quality, precise welded pipes with remarkable speed and consistency. Designed for producing round pipes with outer diameters from φ20 to φ63.5mm and wall thicknesses of 0.8 to 3.0mm, this line represents a significant investment in productivity and quality. By automating the entire process from uncoiling to cutting, it minimizes manual labor, reduces material waste, and ensures uniform output—key factors for staying competitive in industries like construction, automotive, and fluid transport. For a deep dive into modern pipe manufacturing processes, authoritative resources like the American Welding Society provide valuable context.

Core Technical Specifications & Finished Product

This pipe production line is engineered for versatility and precision.

-

Raw Material: Processes hot-rolled or cold-rolled low-carbon steel coils.

-

Finished Product Range: Produces round pipes with an outer diameter (OD) of φ20–63.5mm and a wall thickness of 0.8–3.0mm.

-

Production Speed: Operates at an impressive speed of 0–80 meters per minute, allowing for high-volume output.

-

Machine Arrangement: Features a split-style layout with feed and side discharge, offering flexibility in factory floor planning.

Step-by-Step Technology Procedures

The efficiency of this Welding Pipe Making Machine Line is rooted in its seamless, automated workflow:

Uncoiling → Butt Shearing & Welding → Horizontal Accumulating → Flattening → Forming → HF Welding → Scraping → Cooling → Sizing → Straightening → Flying Cut-Off → Run Out Table.

Each stage is crucial, with high-frequency (HF) welding serving as the core technology that creates a strong, consistent weld seam. The process is designed for continuous operation, with accumulators allowing for coil changes without stopping the line.

Detailed Breakdown of Key Machine Line Components

1. Uncoiler & Entry Section

The process begins with a double-roll, air-expanding uncoiler designed for coils up to φ1600mm OD, 200mm width, and 2 Metric Tons in weight. Paired with a pneumatic butt shear and welding machine, this section prepares the coil ends for a continuous feed, ensuring no interruptions in the tube manufacturing process.

2. Horizontal Spiral Accumulator

This vital component acts as a buffer, storing up to 200 meters of material. It allows the entry section (uncoiling, shearing, welding) to operate intermittently while the main forming and welding line runs continuously at full speed, maximizing overall equipment effectiveness (OEE).

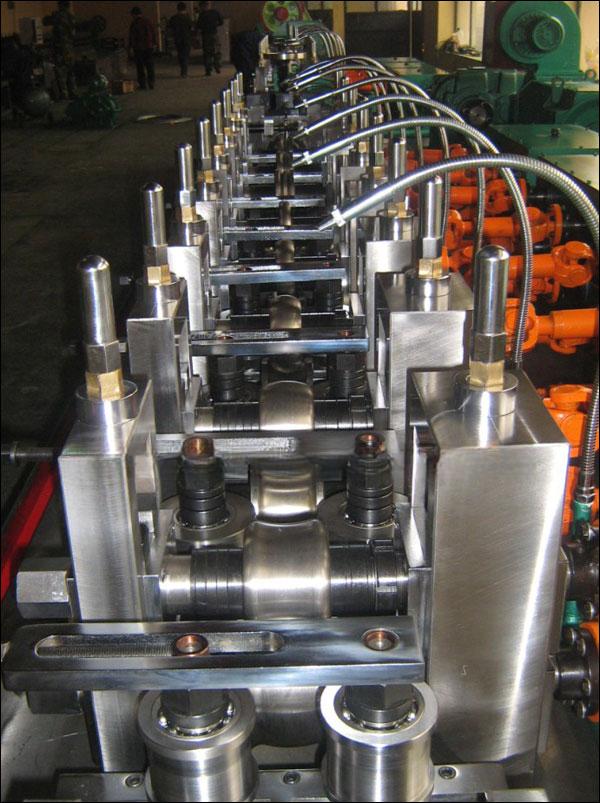

3. Forming & High-Frequency Welding Station

Here, the flattened steel strip is progressively shaped into a cylindrical form. The forming stands utilize a bottom-line horizontal roller theory with double-radius holes. The shaped strip then enters the heart of the Welding Pipe Making Machine Line: the HF welding station. This system uses a high-frequency electrical current to heat the edges to a forging temperature instantly, where they are fused under pressure from squeeze rolls. According to studies on ScienceDirect, HF welding is prized for its speed and the high-integrity welds it produces on low-carbon steels.

4. Sizing, Straightening & Precision Cutting

After welding and initial cooling, the pipe passes through sizing stands that calibrate it to the exact final diameter. A “turkey head” straightening device ensures perfect longitudinal straightness. The line culminates in a computer-controlled flying saw, which cuts the moving pipe to specified lengths (4–10 meters) with an accuracy of ±3mm at full line speed, without stopping production.

The Unbeatable Advantages of an Integrated Pipe Making Line

Investing in a complete Welding Pipe Making Machine Line offers transformative benefits:

-

High Efficiency & Output: Speeds up to 80 m/min enable mass production.

-

Superior Consistency & Quality: Automated control at every stage guarantees uniform pipe dimensions and weld integrity.

-

Remarkable Material Yield: Precise cutting and continuous processing minimize scrap.

-

Operational Flexibility: Quick adjustments allow for producing different pipe sizes within the machine’s range, responding swiftly to market demands.

-

Reduced Labor Costs: High automation minimizes the need for manual intervention.

Contact us for more details or send your inquire to us.