STEEL TILE PANEL FORMING MACHINE

— steel tile cold roll forming machine

Main Technical Parameter

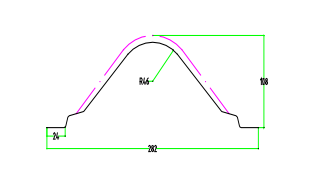

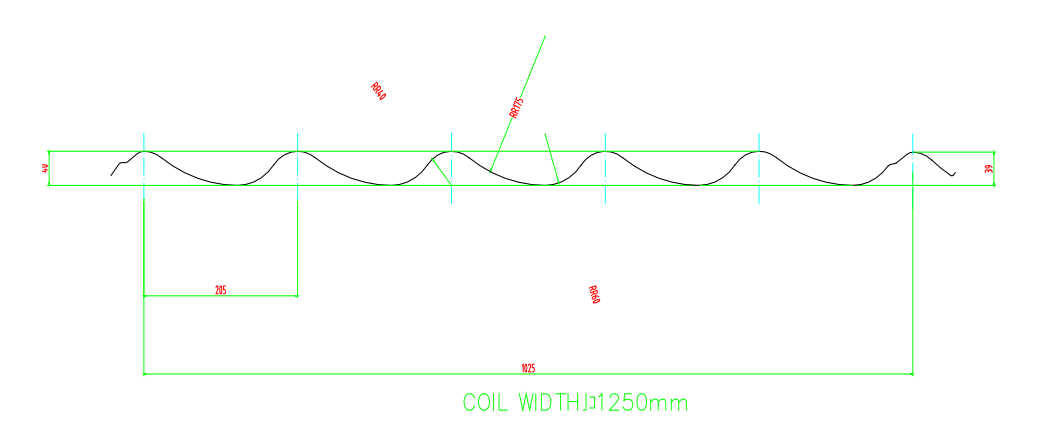

1:size of sheet(mm): 1250×(0.4~0.6)×L

2: working speed:2m–3m/min

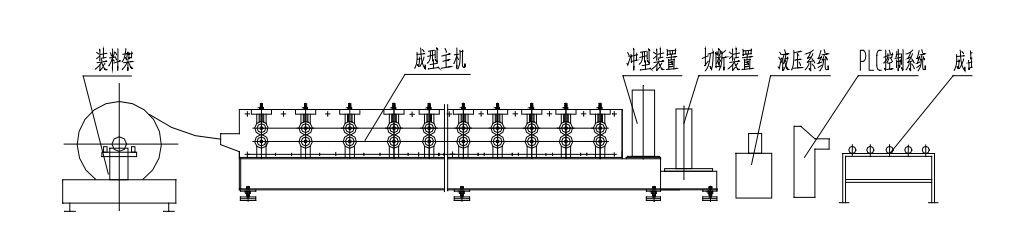

3: roll station: 16stations

4: material of roller: 45#forge steel, polished and coated with chrome

5:material of main shaft:45﹟forge steel

6: main power: 4.5kw

7: hydraulic station power: 5.5kw

8: Hydraulic pressure: 10-12Mpa

9: control system: PLC, Panasonic

10:size of machine: 9000×1700×1400(mm)

11: total weight: about 7000kg

main features and components of the machine

1、main features

a、the structure is simple and the appearance of the machine is beautiful because we

adopt the shape-steel structure and process as a whole after welding. it has the ability of

strong loading and stable operation when running the machine.

b.All the components of machine are from brand-famous enterprise so that they ensure

the machine normal function very effectively.

c、we adopt the automatic length-fixed forming and cutting to guarantee the length to be

precise and the finished product clear without deforming .

d: it is very easy to install the equipment and suitable for producing in the factory.

e: the machine has features of low noise and high efficiency.

Technological process

Decoiling—Feeding—cut to length—product packing manual

The type pursues board(basis on customer’s require to design)

Guarantee:

1:Guaranteed against malfunctions due to manufacturing defects for 1 year after date

of purchase. Repairs will be made free of charge.

2:Reparis will not be performed free of change even during the guarantee period in

the follow circumstances

– damage occurs due to a natural disaster

– malfunction occurs due to user error

– malfunction occurs due to modifications

– malfunction occurs due to further movement or shipment after installation

3:Air ticket, transportation cost, hotel, meals and 30$ per day shall be for purchaser’s

account if manufacturer’s engineer has to be send to purchaser’s factory to maintain

the machine during the guarantee period.